Infiniti FX35, FX50 (S51). Manual - part 955

EM-120

< UNIT DISASSEMBLY AND ASSEMBLY >

[VQ35HR]

CYLINDER BLOCK

Screw M8 bolt [pitch: 1.25 mm (0.0492 in) length: approximately

50 mm (1.97 in)] into bolt holes (A). Then equally tighten each

bolt, and remove lower cylinder block.

CAUTION:

• Be careful not to damage the mounting surfaces.

• Never tighten bolts too much.

• Never insert screw driver, this will damage the mating sur-

face.

10. Remove crankshaft.

11. Pull rear oil seal out from rear end of crankshaft.

12. Remove main bearings and thrust bearings from cylinder block and lower cylinder block.

CAUTION:

• Be careful not to drop main bearing, and to scratch the surface.

• Identify installation positions, and store them without mixing them up.

13. Remove oil jet.

ASSEMBLY

1.

Fully air-blow engine coolant and engine oil passages in cylinder block, cylinder bore and crankcase to

remove any foreign material.

CAUTION:

Use a goggles to protect your eye.

2.

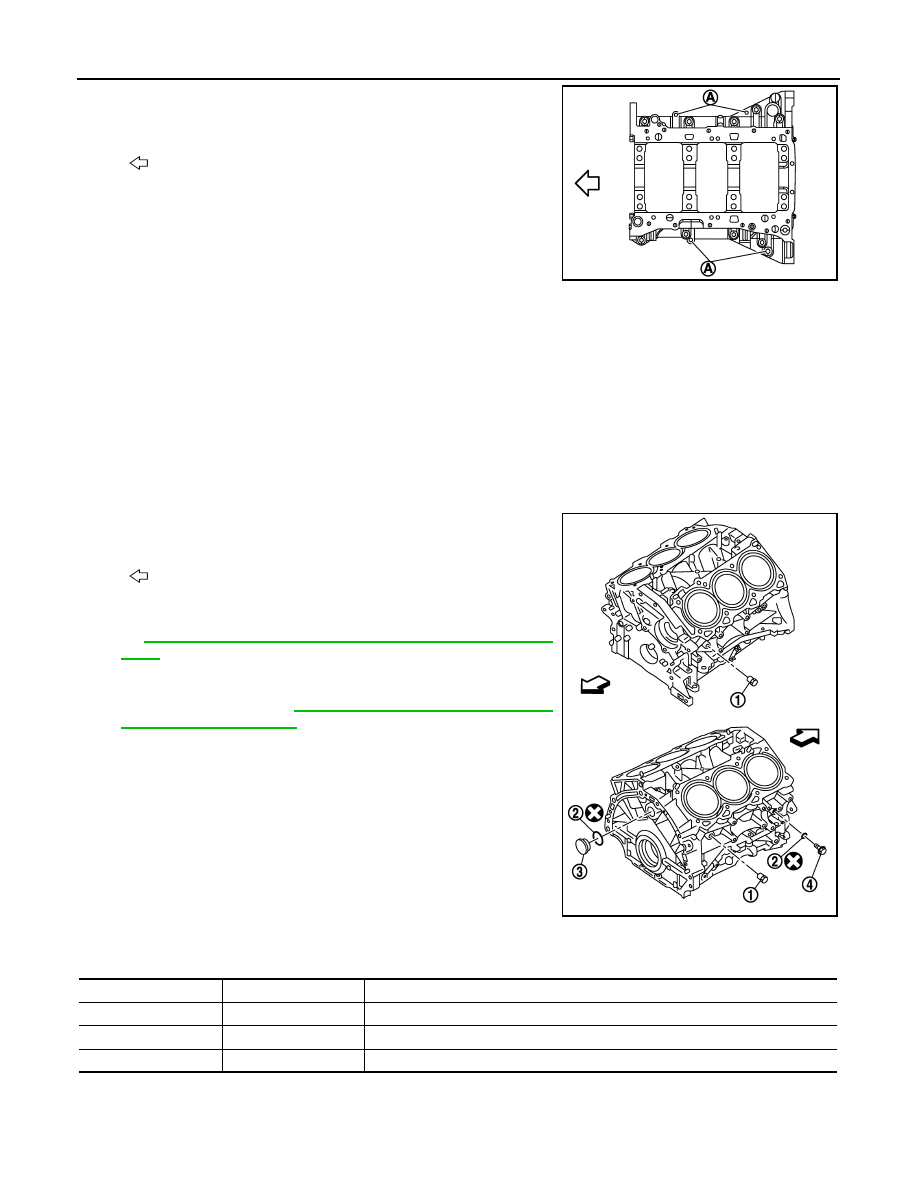

Install each plug to cylinder block as shown in the figure.

• Apply sealant to the thread of water drain plugs (1), (4).

Use Genuine RTV Silicone Sealant or an equivalent. Refer

to

GI-16, "Recommended Chemical Products and Seal-

.

• Apply sealant to the thread of plugs.

Use Genuine high strength thread locking sealant or an

equivalent. Refer to

• Replace washers (2) with new one.

• Tighten each plug as specified below.

3.

Install oil jet.

: Engine front

JPBIA0414ZZ

3

: Plug

: Engine front

JPBIA0191ZZ

Part

Washer

Tightening torque

1

No

19.6 N·m (2.0 kg-m, 14 ft-lb)

3

Yes

78.0 N·m (8.0 kg-m, 58 ft-lb)

4

Yes

12.3 N·m (1.3 kg-m, 9 ft-lb)