Infiniti FX35, FX50 (S51). Manual - part 953

EM-112

< UNIT DISASSEMBLY AND ASSEMBLY >

[VQ35HR]

CYLINDER HEAD

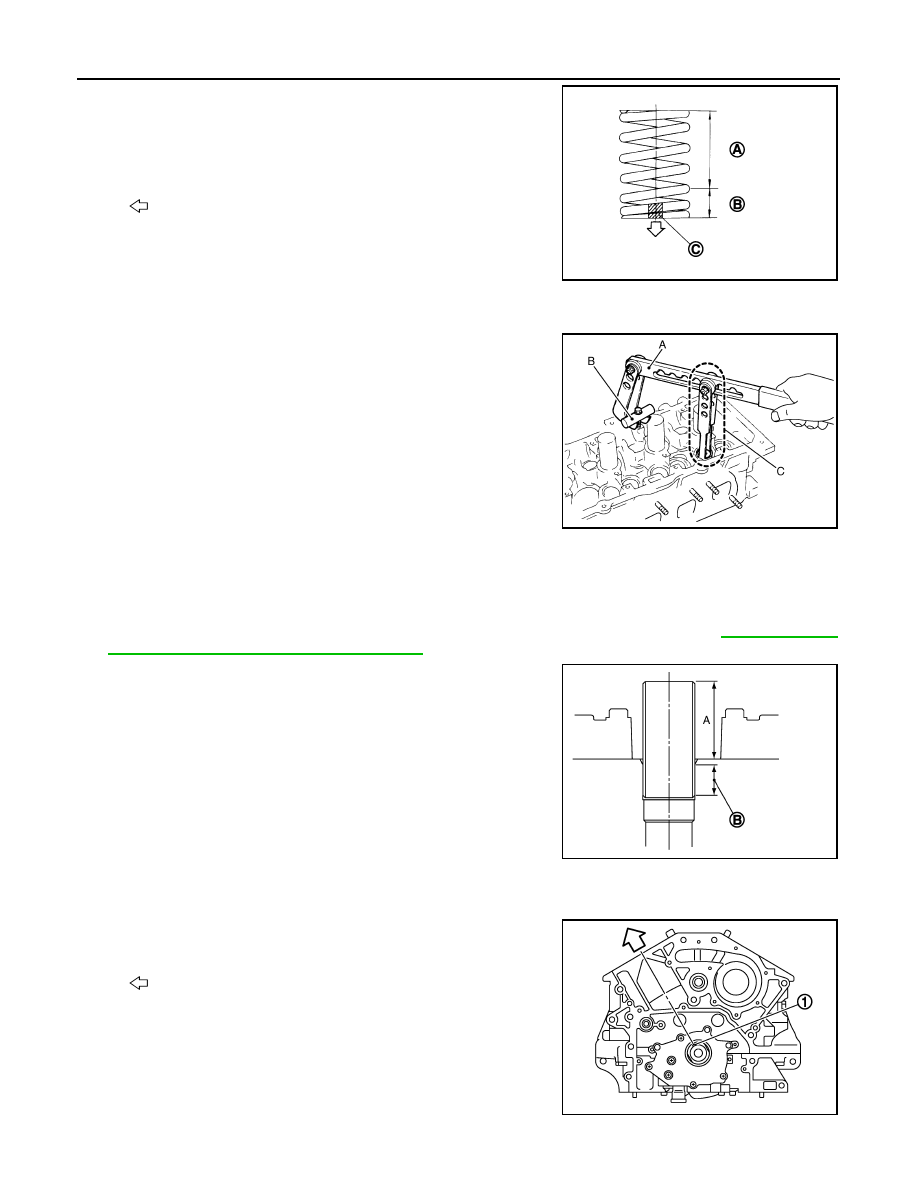

• Install narrow pitch end to cylinder head side (valve spring

seat side).

7.

Install valve spring retainer.

8.

Install valve collet.

• Compress valve spring with the valve spring compressor [SST:

KV10116200 (J-26336-A)] (A), the attachment [SST:

KV10115900 (J-26336-20)] (C) and the adapter [SST:

KV10116200 (

—

)] (B). Install valve collet with a magnet

hand.

CAUTION:

When working, take care not to damage valve lifter holes.

• Tap valve stem edge lightly with plastic hammer after installa-

tion to check its installed condition.

9.

Install spark plug tube.

• Press-fit spark plug tube as per the following:

a.

Remove old locking sealant adhering to cylinder head mounting hole.

b.

Apply sealant to area within approximately 12 mm (0.47 in) from edge of spark plug tube press-fit side.

Use Genuine high strength thread locking sealant or an equivalent. Refer to

mended Chemical Products and Sealants"

c.

Using drift, press-fit spark plug tube so that its height (A) is as

specified in the figure.

CAUTION:

• When press-fitting, take care not to deform spark plug

tube.

• After press-fitting, wipe out liquid gasket protruding onto

cylinder-head upper face.

10. Install new cylinder head gaskets.

11. Turn crankshaft until No. 1 piston is set at TDC.

• Crankshaft key should line up with the bank 1 cylinder center

line as shown in the figure.

A

: Wide pitch

B

: Narrow pitch

C

: Paint mark

: Cylinder head side

Paint mark color

: Yellowish green

JPBIA0179ZZ

JPBIA0180ZZ

B

: High strength thread locking sealant application area

Standard press-fit height:

: 37.7 - 38.7 mm (1.484 - 1.524 in)

1

: Crankshaft key

: Bank 1 side

JPBIA0181ZZ

JPBIA0174ZZ