Infiniti FX35, FX50 (S51). Manual - part 731

COOLING FAN

EC-465

< DTC/CIRCUIT DIAGNOSIS >

[VQ35HR]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

3.

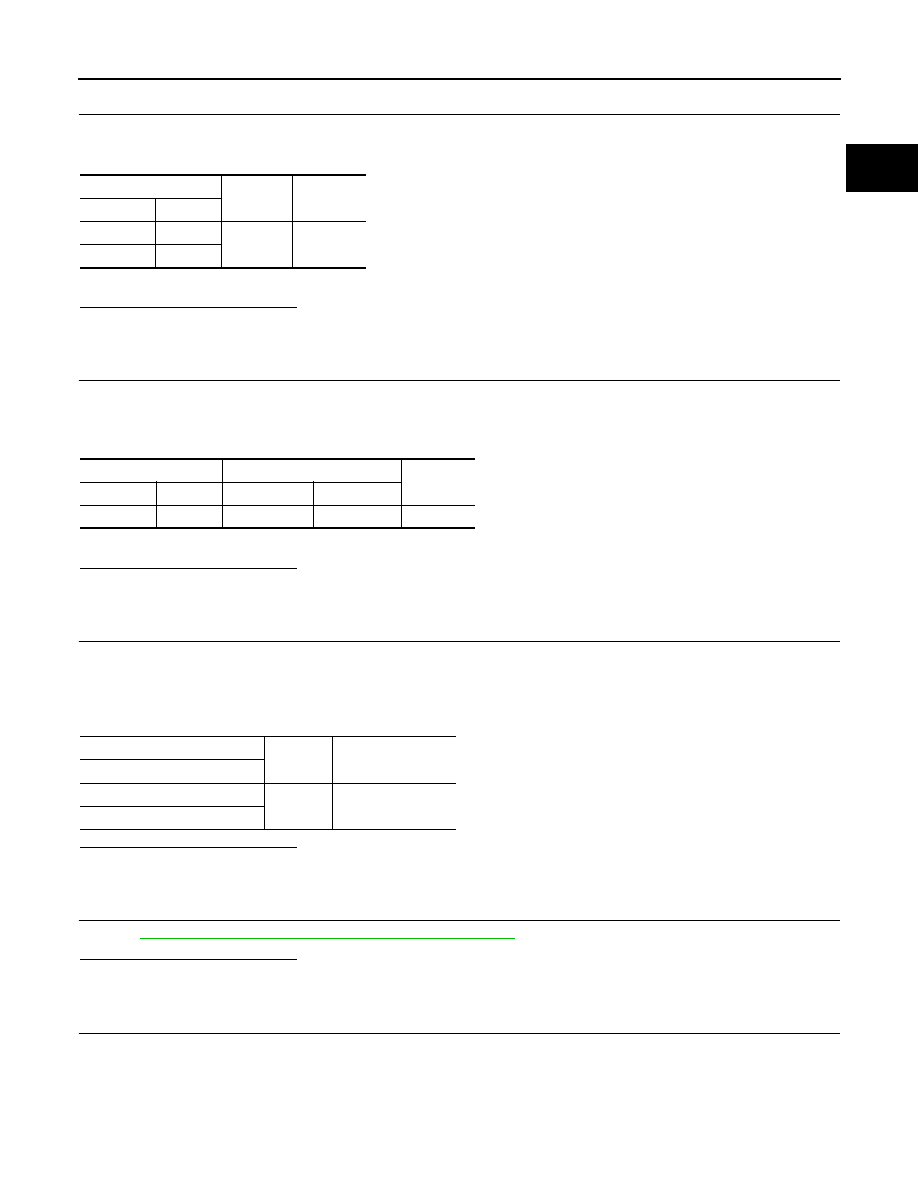

CHECK IPDM E/R GROUND CIRCUIT

1.

Disconnect IPDM E/R harness connectors E5, E6.

2.

Check the continuity between IPDM E/R harness connector and ground.

3.

Also check harness for short to power.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair open circuit or short to power in harness or connectors.

4.

CHECK COOLING FAN CONTROL SIGNAL CIRCUIT

1.

Disconnect IPDM E/R harness connector E9.

2.

Check the continuity between IPDM E/R harness connector and cooling fan control module 1 harness

connector.

3.

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Repair open circuit, short to ground or short to power in harness or connectors.

5.

CHECK COOLING FAN CONTROL MODULE 1 OUTPUT SIGNAL CIRCUIT

1.

Reconnect all harness connectors disconnected.

2.

Disconnect cooling fan control module 1 harness connectors E301, E302.

3.

Turn ignition switch ON.

4.

Check the voltage between cooling fan control module 1 terminals and ground.

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> Replace cooling fan control module 1.

6.

CHECK COOLING FAN MOTORS -1 AND -2

EC-466, "Component Inspection (Cooling Fan Motor)"

Is the inspection result normal?

YES

>> GO TO 11.

NO

>> Replace malfunctioning cooling fan motor.

7.

CHECK COOLING FAN CONTROL MODULE 1 POWER SUPPLY CIRCUIT-II

1.

Turn ignition switch OFF.

2.

Disconnect cooling fan relay 1.

3.

Turn ignition switch ON.

4.

Check the voltage between cooling fan relay 1 harness connector and ground.

IPDM E/R

Ground

Continuity

Connector

Terminal

E5

12

Ground

Existed

E6

41

IPDM E/R

Cooling fan control module 1

Continuity

Connector

Terminal

Connector

Terminal

E9

97

E37

2

Existed

Cooling fan control module 1

Ground

Voltage

Terminal

4

Ground

Battery voltage

6