Infiniti FX35, FX50 (S51). Manual - part 624

ENGINE CONTROL SYSTEM

EC-37

< SYSTEM DESCRIPTION >

[VQ35HR]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

Component Description

INFOID:0000000005236697

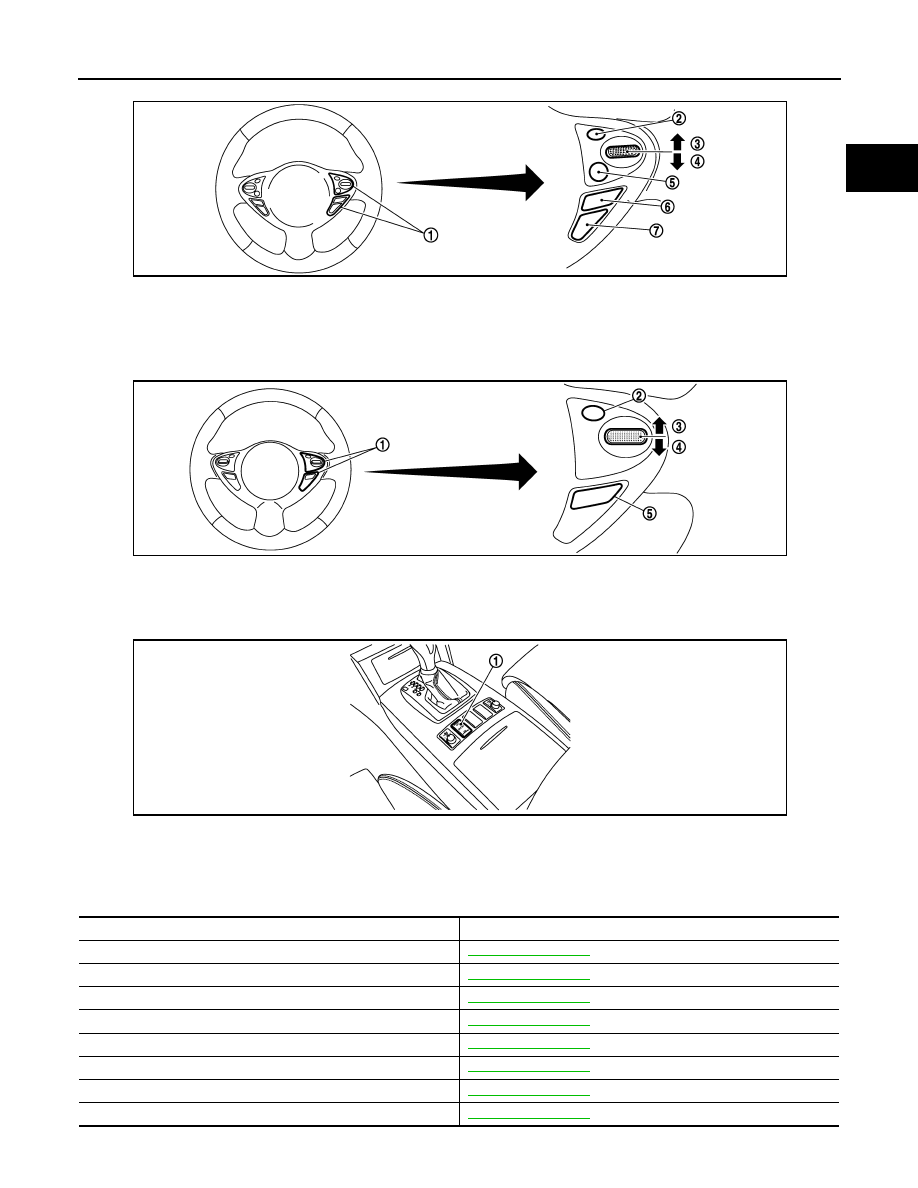

1.

ICC steering switch

2.

CANCEL switch

3.

RESUME/ACCELERATE switch

4.

SET/COAST switch

5.

DISTANCE switch

6.

MAIN switch

7.

LDP/DCA switch

1.

ASCD steering switch

2.

CANCEL switch

3.

RESUME/ACCELERATE switch

4.

SET/COAST switch

5.

MAIN switch

1.

Snow mode switch

JSBIA0155ZZ

JSBIA0156ZZ

JMBIA1623ZZ

Component

Reference

A/F sensor 1

A/F sensor 1 heater

Accelerator pedal position sensor

ASCD brake switch

ASCD steering switch

Battery current sensor

Camshaft position sensor

Crankshaft position sensor