Infiniti FX35, FX50 (S51). Manual - part 590

FRONT OIL SEAL

DLN-195

< REMOVAL AND INSTALLATION >

[REAR FINAL DRIVE: R200]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

8.

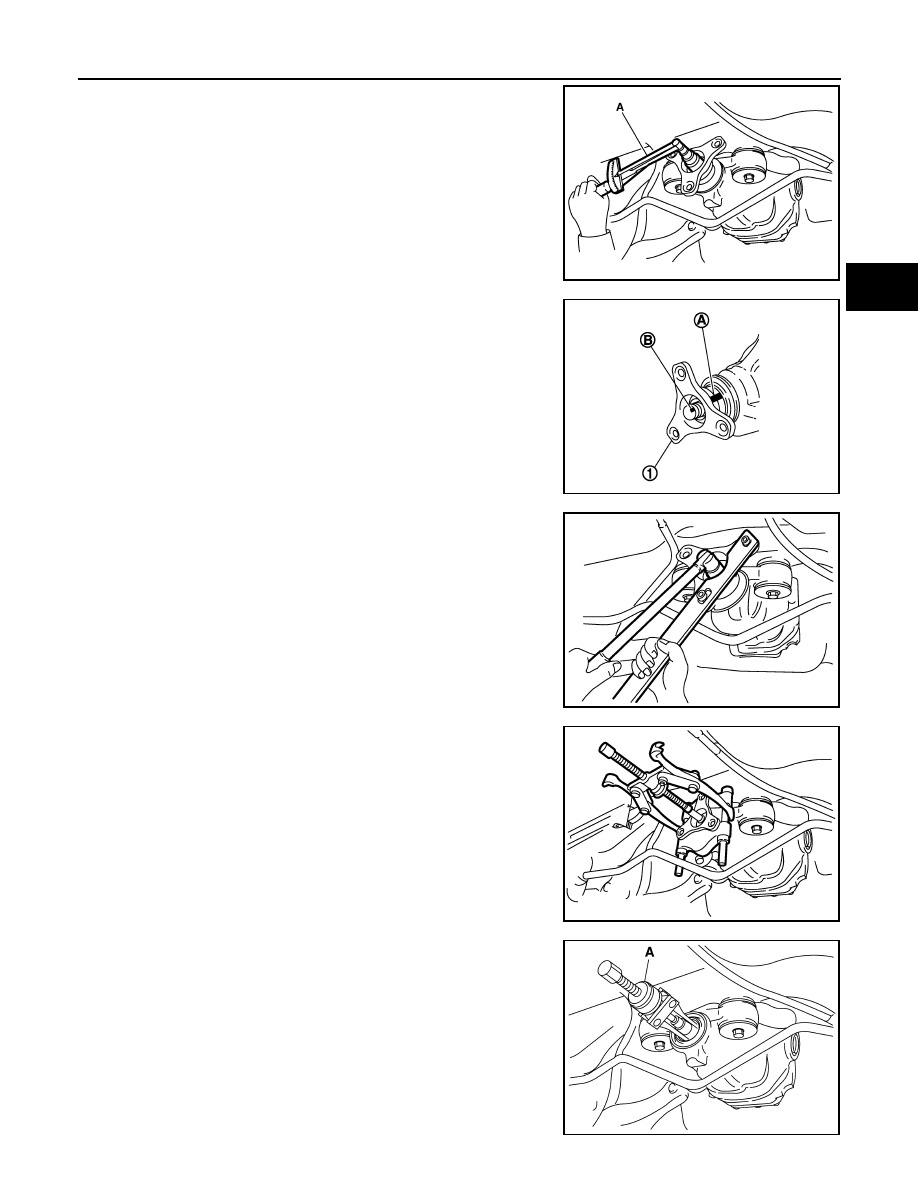

Measure the total preload with the preload gauge (A) [SST:

ST3127S000 (J-25765-A)].

NOTE:

Record the preload measurement.

9.

Put matching mark (B) on the end of the drive pinion. The

matching mark (B) should be in line with the matching mark (A)

on companion flange (1).

CAUTION:

For matching mark, use paint. Never damage companion

flange and drive pinion.

NOTE:

The matching mark (A) on the final drive companion flange (1)

indicates the maximum vertical runout position.

10. Remove drive pinion lock nut using the flange wrench.

11. Remove companion flange using pullers.

12. Remove front oil seal using the puller (A) [SST: KV381054S0 (J-

34286)].

JSDIA0015ZZ

JSDIA0016ZZ

JSDIA0021ZZ

JSDIA0022ZZ

PDIA0980E