Content .. 1887 1888 1889 1890 ..

Infiniti FX35, FX50 (S51). Manual - part 1889

TRANSMISSION ASSEMBLY

TM-363

< UNIT REMOVAL AND INSTALLATION >

[7AT: RE7R01B (VK50VE)]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

• Never disassemble.

• Never allow metal filings, etc. to get on the sensor's front edge magnetic area.

• Never place in an area affected by magnetism.

8.

Remove rear plate cover. Refer to

.

9.

Turn crankshaft, and remove the four tightening bolts for drive plate and torque converter.

CAUTION:

When turning the crankshaft, turn it clockwise as viewed from the front of the engine.

10. Remove A/T fluid cooler tube from the A/T assembly and engine. Refer to

.

11. Plug up openings such as the A/T fluid cooler tube hole.

12. Support A/T assembly with a transmission jack.

CAUTION:

When setting the transmission jack, be careful not to allow it to collide against the drain plug.

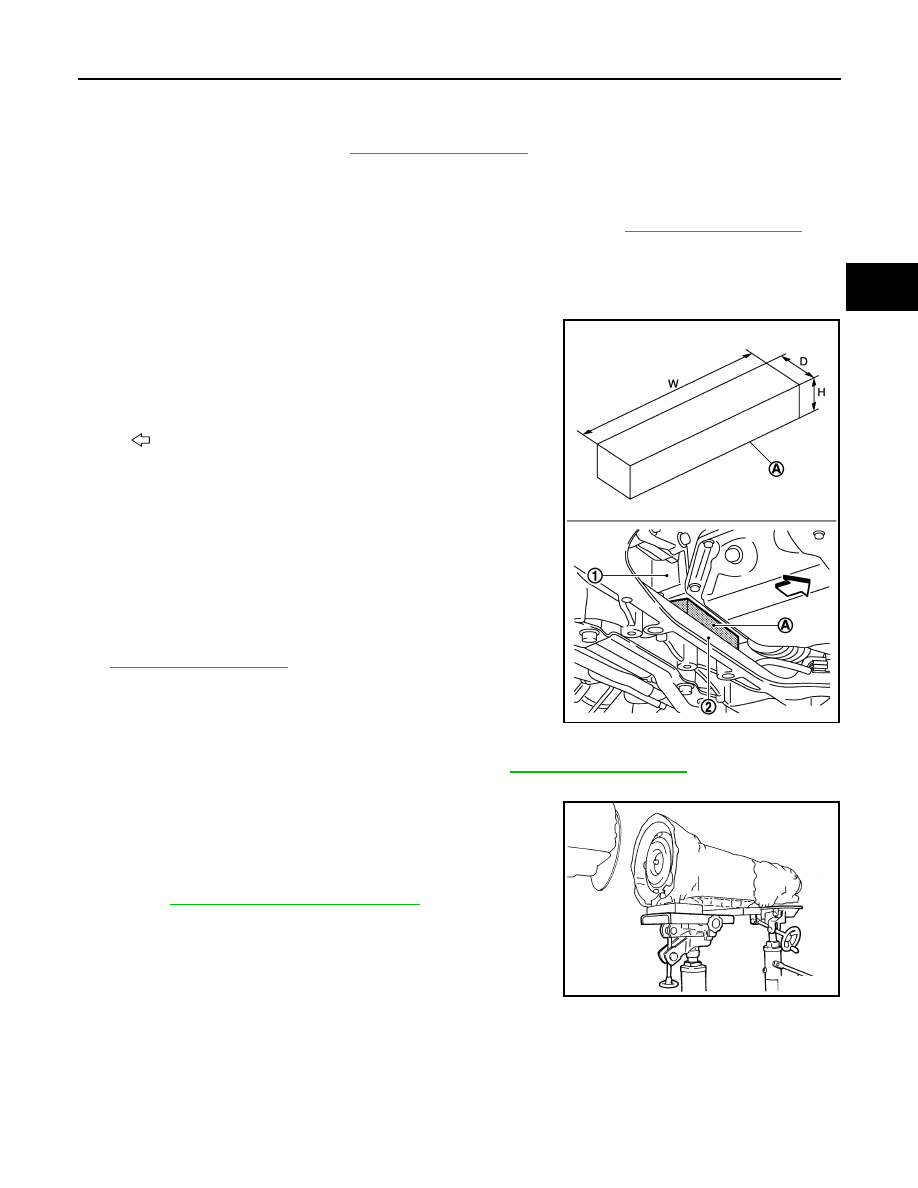

13. Insert a wooden block (A) between oil pan (upper) (1) of engine

and front suspension member (2).

CAUTION:

• Always insert a wooden block between oil pan (upper) of

engine and front suspension member when removing A/T

assembly from the engine. (Because VVEL control shaft

position sensor may be damaged by the interference

between VVEL control shaft position sensor and dash

panel if the operation is performed without the wooden

block inserted.)

• After inserting wooden block, check it does not fall out

easily.

14. Remove rear engine mounting member with power tool. Refer to

.

15. Disconnect A/T assembly connector and AWD solenoid connec-

tor.

16. Remove harness and brackets.

17. Remove bolts fixing A/T assembly to engine with power tool.

18. Remove air breather hose and air breather vent. Refer to

.

19. Remove A/T assembly with transfer assembly from vehicle.

CAUTION:

• Secure torque converter to prevent it from dropping.

• Secure A/T assembly to a transmission jack.

20. Remove transfer assembly from A/T assembly with power tool.

DLN-67, "VK50VE : Exploded View"

.

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

W

: 150 mm (5.91 in)

D

: 30 mm (1.18 in)

H

: 20 mm (0.79 in)

: Vehicle front

JPDIA0923ZZ

SCIA2203E