Content .. 1839 1840 1841 1842 ..

Infiniti FX35, FX50 (S51). Manual - part 1841

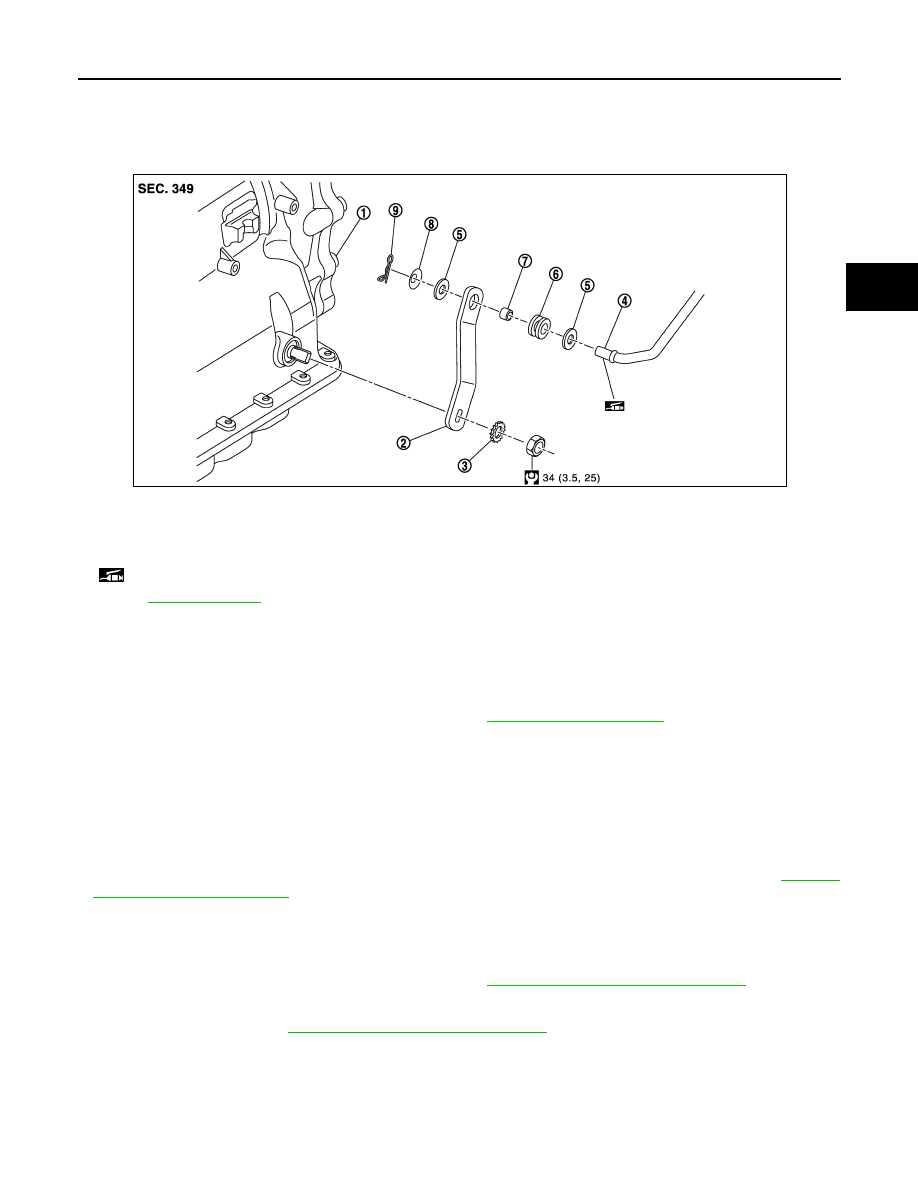

CONTROL ROD

TM-171

< REMOVAL AND INSTALLATION >

[7AT: RE7R01A (VQ35HR)]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

CONTROL ROD

Exploded View

INFOID:0000000005250154

Removal and Installation

INFOID:0000000005250155

REMOVAL

1.

Shift the selector lever to “P” position.

2.

Disconnect A/T shift selector and control rod. Refer to

.

3.

Remove manual lever from A/T assembly.

4.

Remove control rod from manual lever.

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

Apply multi-purpose grease on the pin surface (that slides after installing collar) of the tip of the con-

trol rod.

• When installing control rod to A/T shift selector assembly, refer to “ADJUSTMENT”. Refer to

.

Inspection and Adjustment

INFOID:0000000005250156

INSPECTION AFTER INSTALLATION

Check A/T positions after adjusting A/T positions. Refer to

TM-349, "Inspection and Adjustment"

ADJUSTMENT AFTER INSTALLATION

Adjust A/T positions. Refer to

TM-349, "Inspection and Adjustment"

1.

A/T assembly

2.

Manual lever

3.

Lock washer

4.

Control rod

5.

Washer

6.

Insulator

7.

Collar

8.

Conical washer

9.

Snap pin

: Apply multi-purpose grease.

for symbols not described on the above.

JSDIA1002GB