Content .. 1756 1757 1758 1759 ..

Infiniti FX35, FX50 (S51). Manual - part 1758

ST-24

< REMOVAL AND INSTALLATION >

LOWER SHAFT

LOWER SHAFT

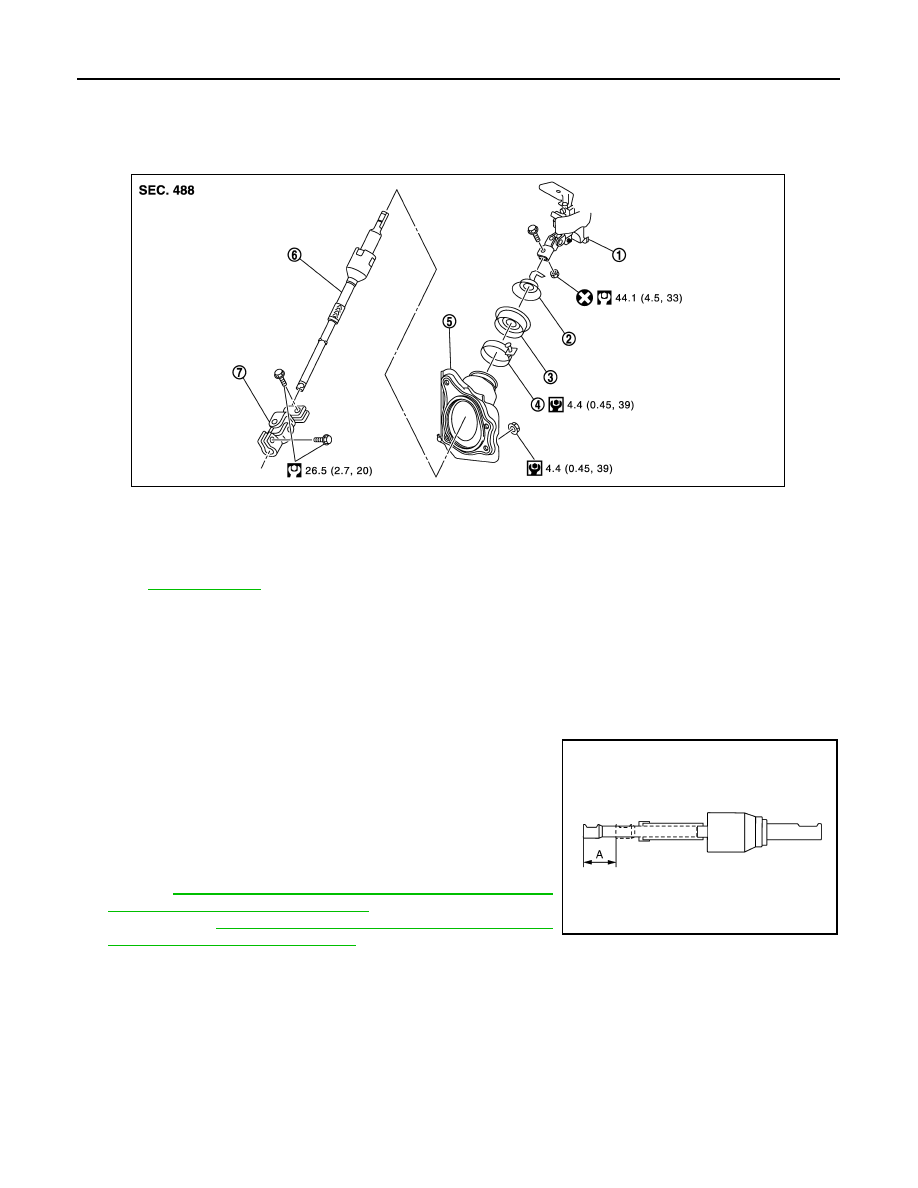

Exploded View

INFOID:0000000005235279

Removal and Installation

INFOID:0000000005235280

REMOVAL

1.

Set the vehicle to the straight-ahead position.

2.

Fix the steering wheel.

3.

Remove lower joint fixing bolt (steering gear side).

4.

Separate the lower shaft from the steering gear assembly by

sliding the slide shaft (A: sliding range).

CAUTION:

Spiral cable may be cut if steering wheel turns while sepa-

rating steering column assembly and steering gear assem-

bly. Be sure to secure steering wheel using string to avoid

turning.

5.

Remove the accelerator pedal bracket and lever assembly.

Refer to

ACC-3, "MODELS WITHOUT DISTANCE CONTROL

ASSIST SYSTEM : Exploded View"

(without distance control

assist system),

ACC-4, "MODELS WITH DISTANCE CONTROL

ASSIST SYSTEM : Exploded View"

(with distance control assist

system).

6.

Remove the parking brake wire clamp stay.

7.

Remove the hole cover mounting nuts.

8.

Remove the upper joint fixing bolt and nut (lower shaft side).

9.

Remove the lower shaft and hole cover.

10. Remove collar, hole cover seal, clamp and hole cover.

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

1.

Steering column assembly

2.

Collar

3.

Hole cover seal

4.

Clamp

5.

Hole cover

6.

Lower shaft

7.

Lower joint

Refer to

for symbols in the figure.

JSGIA0357GB

JSGIA0035ZZ