Content .. 1306 1307 1308 1309 ..

Infiniti FX35, FX50 (S51). Manual - part 1308

LAN-174

< DTC/CIRCUIT DIAGNOSIS >

[CAN SYSTEM (TYPE 3)]

ITS COMMUNICATION CIRCUIT

ITS COMMUNICATION CIRCUIT

Diagnosis Procedure

INFOID:0000000005576986

1.

CHECK CAN DIAGNOSIS

Check the CAN diagnosis results from CONSULT-III to see that the CAN communication circuit has no mal-

function.

NOTE:

For identification of CAN communication circuit and ITS communication circuit, refer to

Is the CAN communication circuit normal?

YES

>> GO TO 2.

NO

>> Check and repair CAN communication circuit.

2.

CONNECTOR INSPECTION

1.

Turn the ignition switch OFF.

2.

Disconnect the battery cable from the negative terminal.

3.

Check the following terminals and connectors for damage, bend and loose connection (unit side and con-

nector side).

-

ICC sensor integrated unit

-

Accelerator pedal actuator

-

Harness connector E106

-

Harness connector M6

-

Harness connector M117

-

Harness connector B201

-

Brake booster control unit

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Repair the terminal and connector.

3.

CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

1.

Disconnect the following harness connectors.

-

ICC sensor integrated unit

-

Brake booster control unit

2.

Check the continuity between the ICC sensor integrated unit harness connector and the brake booster

control unit harness connector.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair the ICC sensor integrated unit branch line. (ITS communication line). Refer to

.

4.

CHECK HARNESS CONTINUITY (SHORT CIRCUIT)

1.

Disconnect the connector of accelerator pedal actuator.

2.

Check the continuity between the ICC sensor integrated unit harness connector terminals.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Check the harness and repair or replace (if shield line is short) the root cause.

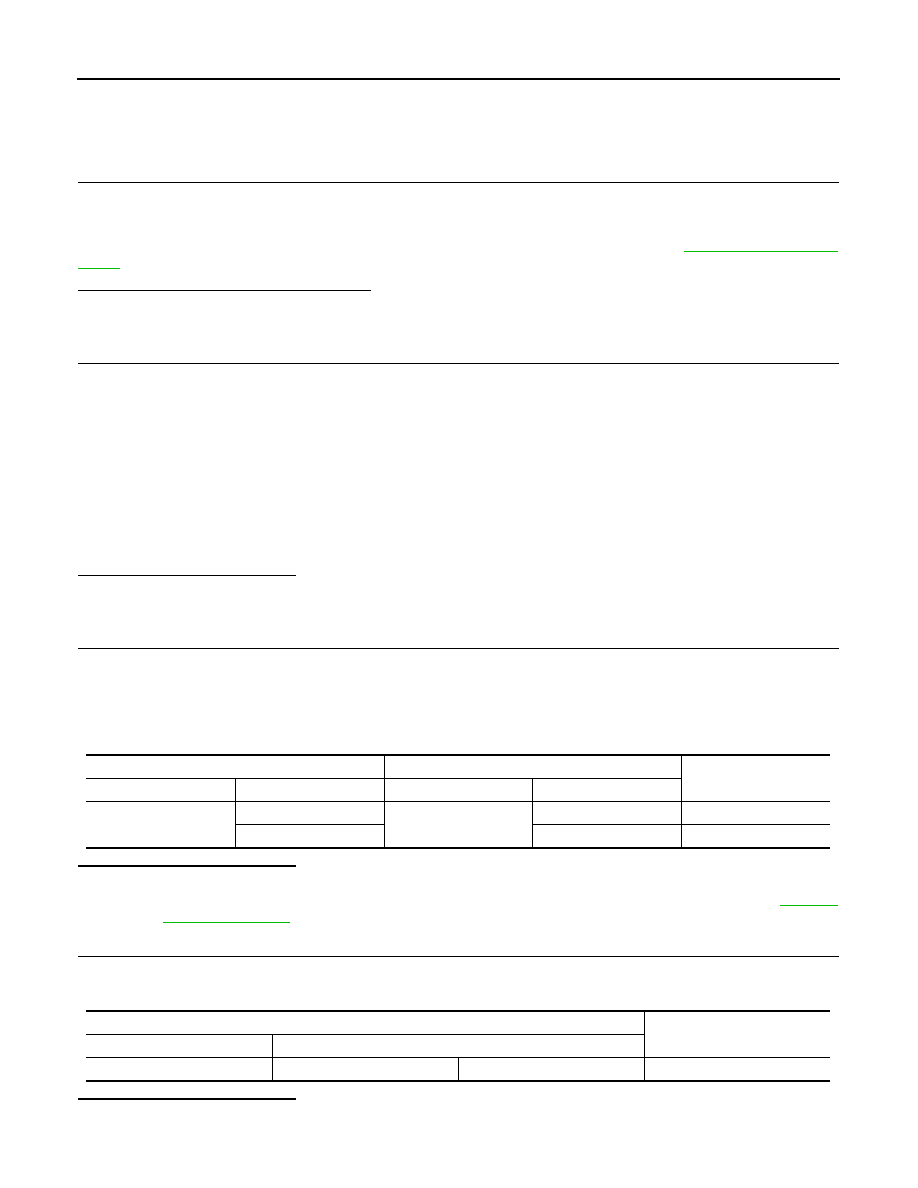

ICC sensor integrated unit harness connector

Brake booster control unit harness connector

Continuity

Connector No.

Terminal No.

Connector No.

Terminal No.

E67

2

B250

14

Existed

5

5

Existed

ICC sensor integrated unit harness connector

Continuity

Connector No.

Terminal No.

E67

2

5

Not existed