Infiniti EX35. Manual - part 732

CYLINDER BLOCK

EM-127

< DISASSEMBLY AND ASSEMBLY >

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

Factory installed parts grading:

• Service parts apply only to grade “0”.

Unit: mm (in)

*: After installing in connecting rod

CYLINDER BLOCK DISTORTION

• Using a scraper, remove gasket on the cylinder block surface, and also remove engine oil, scale, carbon, or

other contamination.

CAUTION:

Be careful not to allow gasket flakes to enter engine oil or engine coolant passages.

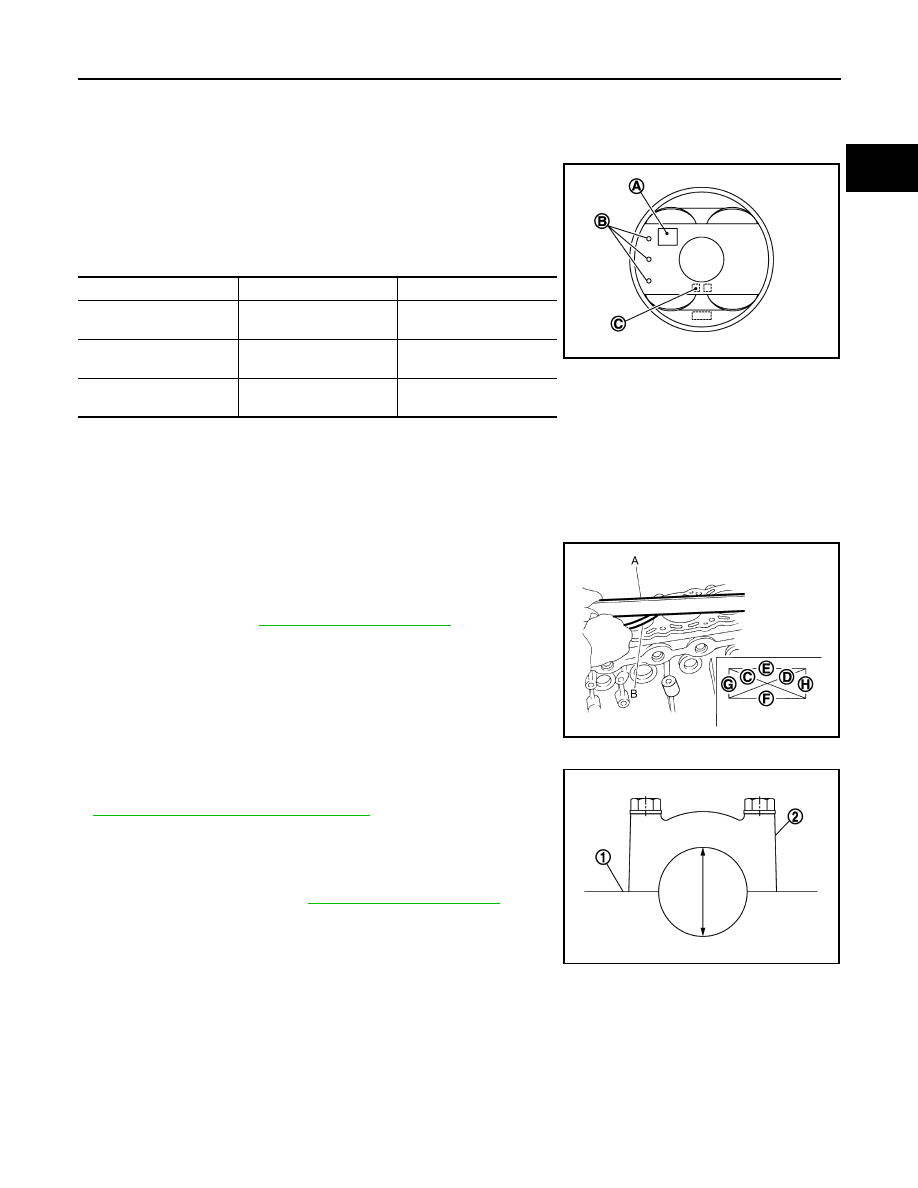

• Measure the distortion on the cylinder block upper face at some

different points in six directions (C, D, E, F, G, and H) with a

straightedge (A) and a feeler gauge (B).

• If it exceeds the limit, replace cylinder block.

MAIN BEARING HOUSING INNER DIAMETER

• Install lower cylinder block (2) without installing main bearings, and

tighten lower cylinder block bolts to the specified torque. Refer to

EM-115, "Disassembly and Assembly"

for the tightening proce-

dure.

• Measure the inner diameter of main bearing housing with a bore

gauge.

• If out of the standard, replace cylinder block (1) and lower cylinder

block as assembly.

NOTE:

Cylinder block cannot be replaced as a single part, because it is

machined together with lower cylinder block.

PISTON TO CYLINDER BORE CLEARANCE

Cylinder Bore inner Diameter

H

: Front mark

I

: Management code

A

: Piston grade number

B

: Front mark

C

: Piston pin grade number

Grade

0

1

Connecting rod bushing

inner diameter *

22.000 - 22.006

(0.8661 - 0.8664)

22.006 - 22.012

(0.8664 - 0.8666)

Piston pin hole diameter

21.993 - 21.999

(0.8659 - 0.8661)

21.999 - 22. 005

(0.8661 - 0.8663)

Piston pin outer diameter

21.989 - 21.995

(0.8657 - 0.8659)

21.995 - 22.001

(0.8659 - 0.8662)

JPBIA0267ZZ

Limit

: Refer to

JPBIA0224ZZ

Standard

: Refer to

.

JPBIA0225ZZ