Infiniti EX35. Manual - part 722

ENGINE ASSEMBLY

EM-87

< REMOVAL AND INSTALLATION >

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

6.

Remove starter motor. Refer to

.

7.

Remove front propeller shaft from the front final drive assembly side. Refer to

.

8.

Separate the engine from the transmission assembly. Refer to

9.

Remove the front final drive assembly from oil pan (upper). Refer to

10. Remove each engine mounting insulator and each engine mounting bracket from the engine with power

tool.

INSTALLATION

Note the following, and install in the reverse order of removal.

• Do not allow engine mounting insulator to be damage and careful no engine oil gets on it.

• For a location with a positioning pin, insert it securely into hole of mating part.

• For a part with a specified installation orientation, refer to component figure in

.

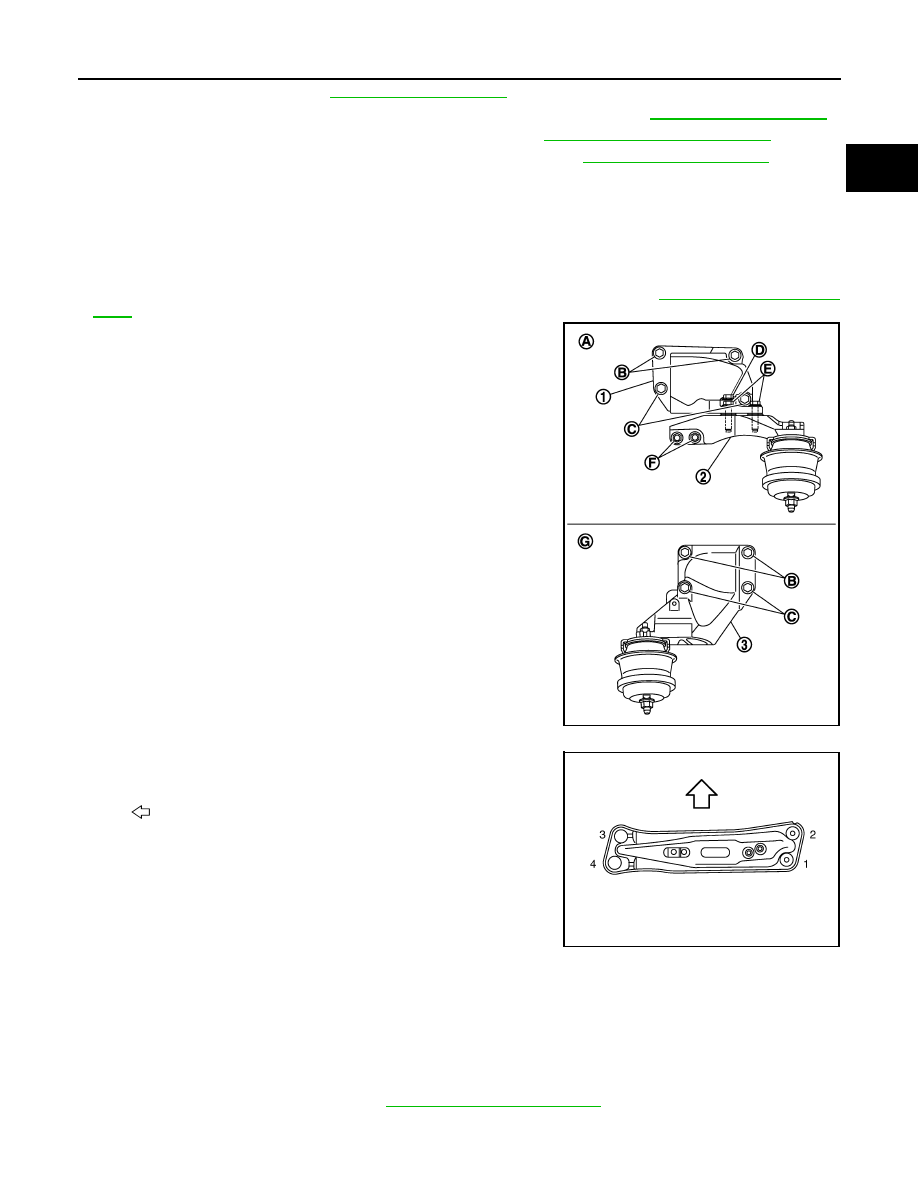

• When installing engine mounting bracket (RH and LH) on cylinder

block, tighten two upper bolts [shown as (B) in the figure] first.

Then tighten two lower bolts [shown as (C) in the figure].

• Install engine mounting bracket (RH) (lower) (2) as follows:

- Temporarily tighten mounting bolts [shown as (D), (E) and (F) in

the figure].

- Tighten mounting bolts to the specified torque with following

mounting surfaces touched.

• Engine mounting bracket (RH) (1) to engine mounting bracket

(RH) (lower) [shown as and in figure].

• Front final drive to engine mounting bracket (RH) (lower) [shown

as in figure].

• Check all engine mounting insulators are seated properly, then

tighten mounting nuts.

• Tighten rear engine mounting member bolts in numerical order as

shown in the figure.

AWD : Inspection

INFOID:0000000003139130

INSPECTION AFTER INSTALLATION

Inspection for Leakage

The following are procedures for checking fluids leakage, lubricates leakage and exhaust gases leakage.

• Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to

MA-10, "Fluids and Lubricants"

.

• Use procedure below to check for fuel leakage.

3

: Engine mounting bracket (LH)

A

: Right side

G : Left side

JPBIA0163ZZ

: Vehicle front

JPBIA0407ZZ