Infiniti EX35. Manual - part 710

FUEL INJECTOR AND FUEL TUBE

EM-39

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

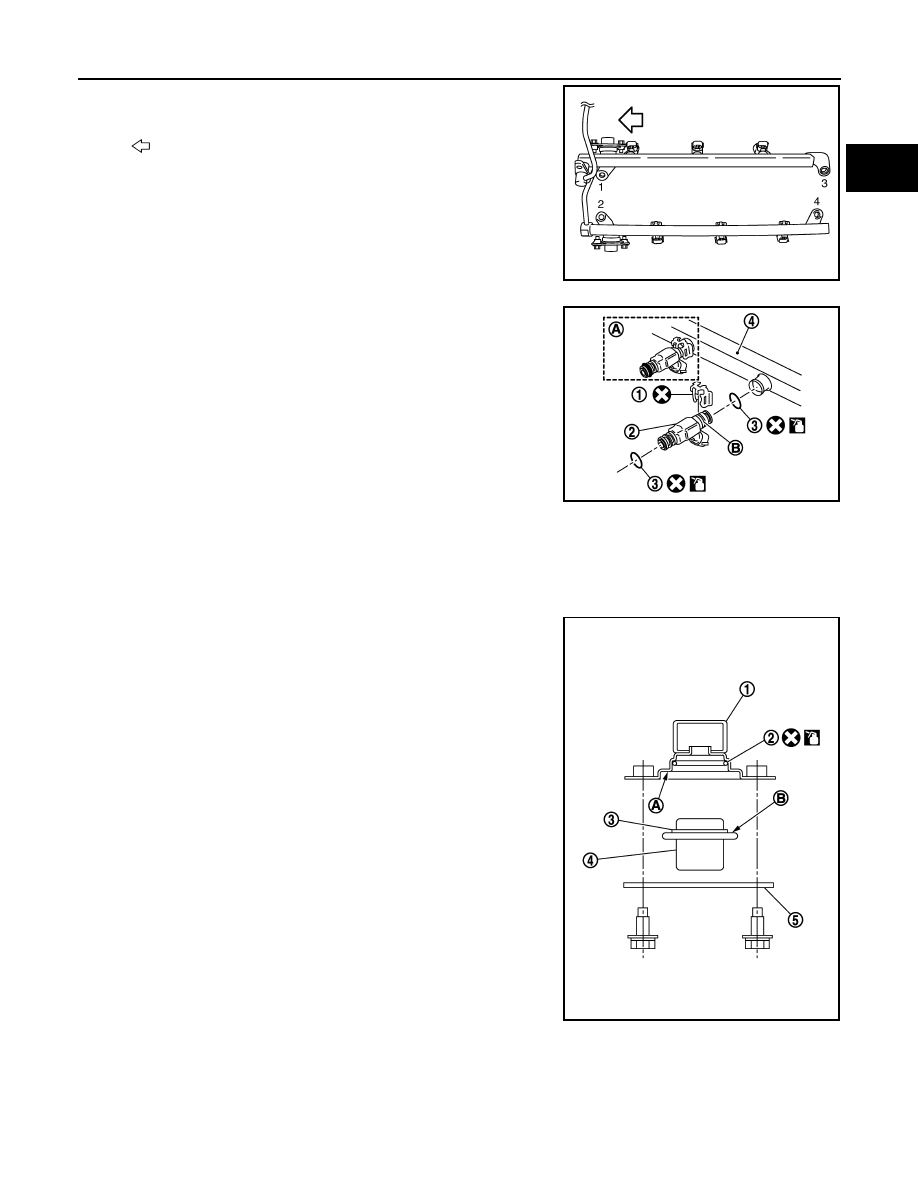

10. Loosen mounting bolts in reverse order as shown in the figure,

and remove fuel tube and fuel injector assembly.

CAUTION:

Never tilt fuel tube, or remaining fuel in pipes may flow out

from pipes.

11. Remove fuel injector (2) from fuel tube (4) as follows:

a.

Open and remove clip (1).

b.

Remove fuel injector from fuel tube by pulling straight.

CAUTION:

• Be careful with remaining fuel that may go out from fuel

tube.

• Be careful not to damage injector nozzles during removal.

• Never bump or drop fuel injector.

• Never disassemble fuel injector.

12. Remove fuel sub-tube and fuel damper, if necessary.

INSTALLATION

1.

Install fuel damper (4) as follows:

a.

Install new O-ring (2) to fuel tube (1) as shown. When handling

new O-ring, be careful of the following caution:

CAUTION:

• Handle O-ring with bare hands. Never wear gloves.

• Lubricate O-ring with new engine oil.

• Never clean O-ring with solvent.

• Check that O-ring and its mating part are free of foreign

material.

• When installing O-ring, be careful not to scratch it with

tool or fingernails. Also be careful not to twist or stretch

O-ring. If O-ring was stretched while it was being

attached, never insert it quickly into fuel tube.

• Insert new O-ring straight into fuel tube. Never twist it.

b.

Install spacer (3) to fuel damper.

c.

Insert fuel damper straight into fuel tube.

CAUTION:

• Insert straight, checking sure that the axis is lined up.

• Never pressure-fit with excessive force.

• Insert fuel damper until (B) is touching (A) of fuel tube.

d.

Tighten bolts evenly in turn.

• After tightening bolts, check that there is no gap between fuel damper cap (5) and fuel tube.

2.

Install fuel sub-tube.

• When handling new O-rings, be careful of the following caution:

CAUTION:

• Handle O-ring with bare hands. Never wear gloves.

: Engine front

JPBIA0034ZZ

3

: O-ring

A

: Installed condition

B

: Clip mounting groove

JPBIA0036ZZ

Reference value

: 130 N (13.3 kg, 29.2 lb)

JPBIA0316ZZ