Infiniti EX35. Manual - part 705

CAMSHAFT VALVE CLEARANCE

EM-19

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

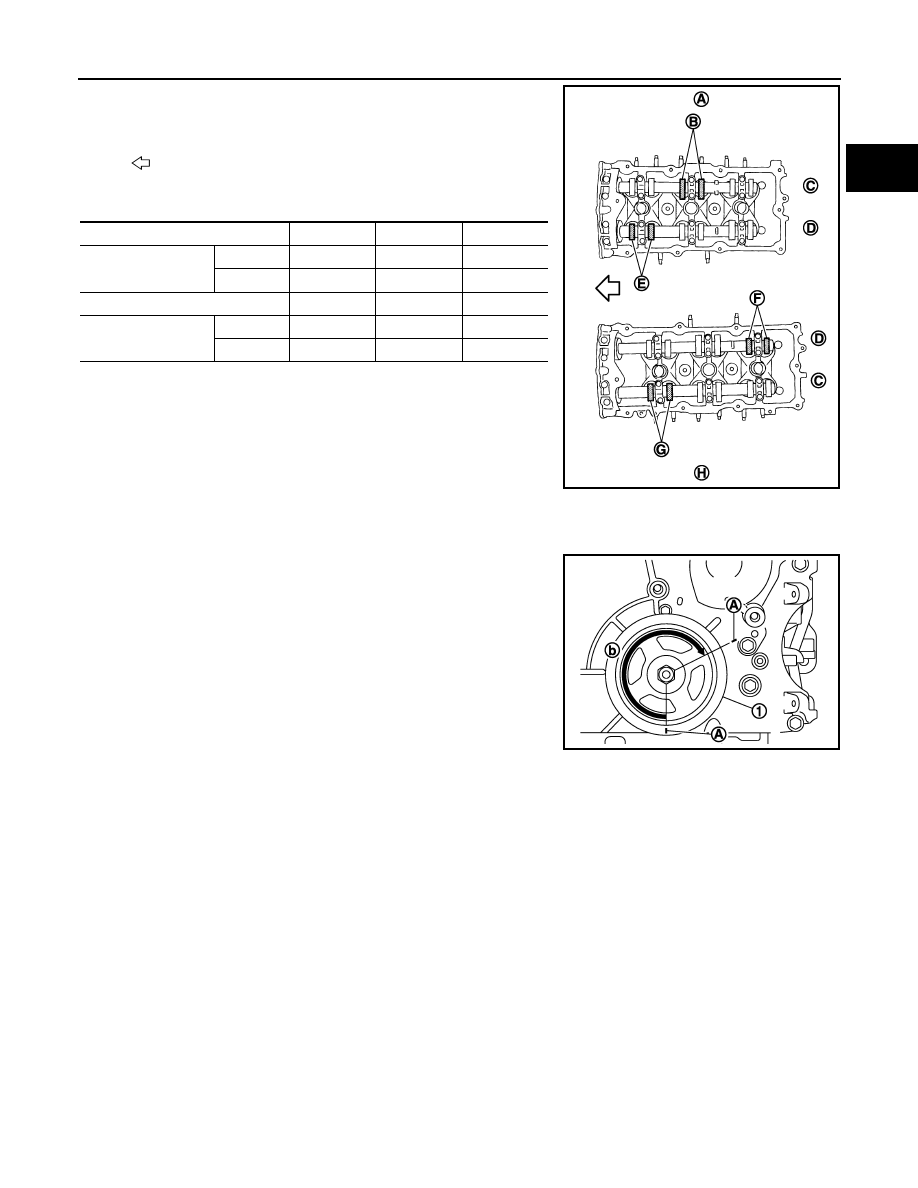

• By referring to the figure, measure the valve clearances at

locations marked “

×

” as shown in the table below (locations

indicated in the figure).

• No. 1 cylinder at compression TDC

c.

Rotate crankshaft 240 degrees clockwise (when viewed from engine front) to align No. 3 cylinder at TDC

its compression stroke.

NOTE:

Mark a position 240 degrees (b) from a corner of the hexagonal

part of crankshaft pulley mounting bolt as shown in the figure.

Use the hexagonal part as a guide.

: Engine front

Measuring position [bank 1 (A)]

No. 1 CYL.

No. 3 CYL.

No. 5 CYL.

No. 1 cylinder at com-

pression TDC

EXH (C)

×

(B)

INT (D)

×

(E)

Measuring position [bank 2 (H)]

No. 2 CYL.

No. 4 CYL.

No. 6 CYL.

No. 1 cylinder at com-

pression TDC

INT (D)

×

(F)

EXH (C)

×

(G)

JPBIA0165ZZ

1

: Crankshaft pulley

A

: Paint mark

JPBIA0166ZZ