Infiniti EX35. Manual - part 699

EC-538

< ON-VEHICLE MAINTENANCE >

[VQ35HR]

FUEL PRESSURE

ON-VEHICLE MAINTENANCE

FUEL PRESSURE

Inspection

INFOID:0000000003133683

FUEL PRESSURE RELEASE

With CONSULT-III

1.

Turn ignition switch ON.

2.

Perform “FUEL PRESSURE RELEASE” in “WORK SUPPORT” mode with CONSULT-III.

3.

Start engine.

4.

After engine stalls, crank it two or three times to release all fuel pressure.

5.

Turn ignition switch OFF.

Without CONSULT-III

1.

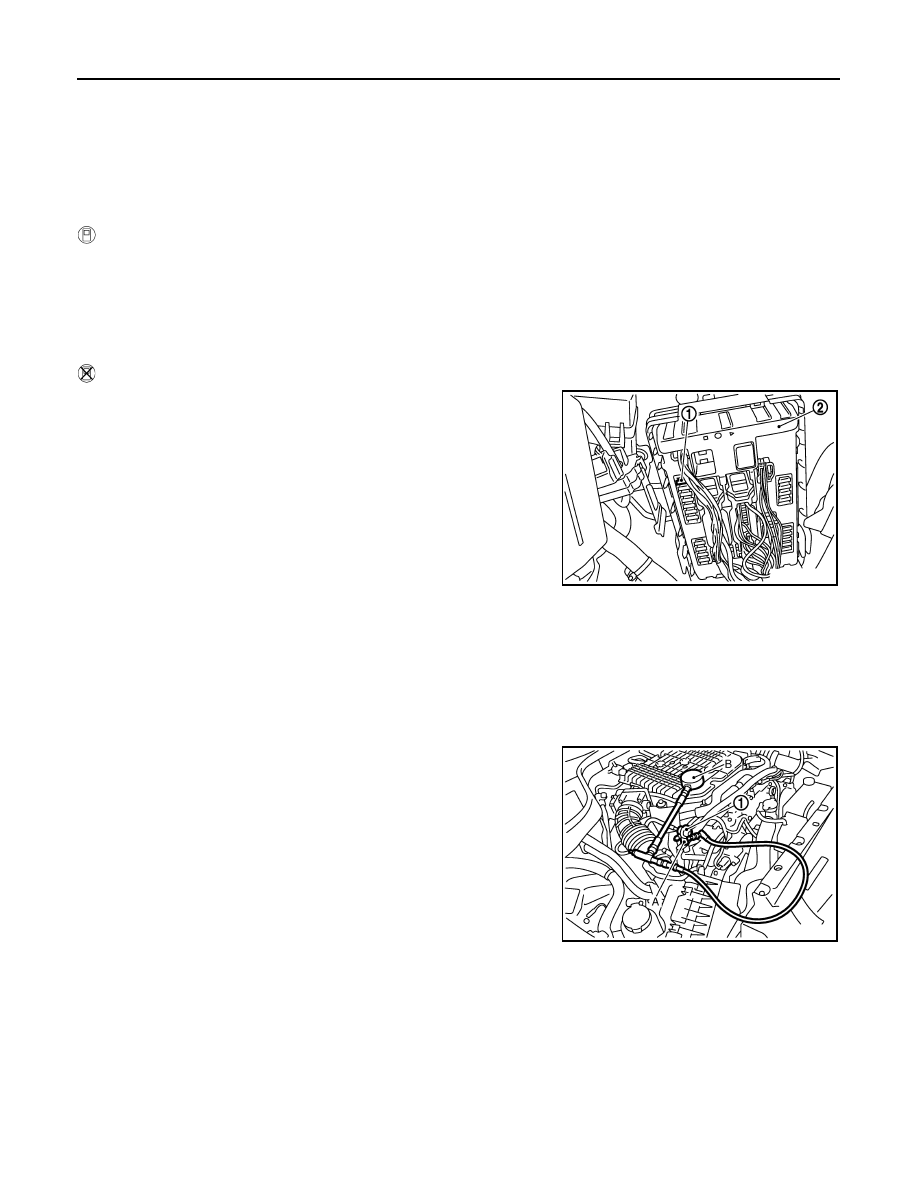

Remove fuel pump fuse (1) located in IPDM E/R (2).

2.

Start engine.

3.

After engine stalls, crank it two or three times to release all fuel

pressure.

4.

Turn ignition switch OFF.

5.

Reinstall fuel pump fuse after servicing fuel system.

FUEL PRESSURE CHECK

CAUTION:

Before disconnecting fuel line, release fuel pressure from fuel line to eliminate danger.

NOTE:

• Prepare pans or saucers under the disconnected fuel line because the fuel may spill out. The fuel

pressure cannot be completely released because J50 models do not have fuel return system.

• Use Fuel Pressure Gauge Kit [SST:(J-44321)] to check fuel pressure.

1.

Release fuel pressure to zero.

2.

Install the inline fuel quick disconnected fitting (A) between fuel

damper (1) and injector tube.

3.

Connect the fuel pressure test gauge (quick connector adapter

hose) (B) to the inline fuel quick disconnected fitting.

4.

Turn ignition switch ON and check for fuel leakage.

5.

Start engine and check for fuel leakage.

6.

Read the indication of fuel pressure gauge.

7.

If result is unsatisfactory, check fuel hoses and fuel tubes for

clogging.

If OK, Replace “fuel filter and fuel pump assembly”.

If NG, Repair or replace malfunctioning part.

JMBIA0021ZZ

At idling

: Approximately 350 kPa (3.57 kg/cm

2

, 51 psi)

JMBIA0028ZZ