Infiniti EX35. Manual - part 654

EC-358

< COMPONENT DIAGNOSIS >

[VQ35HR]

P1226, P1235 TP SENSOR

P1226, P1235 TP SENSOR

Description

INFOID:0000000003133517

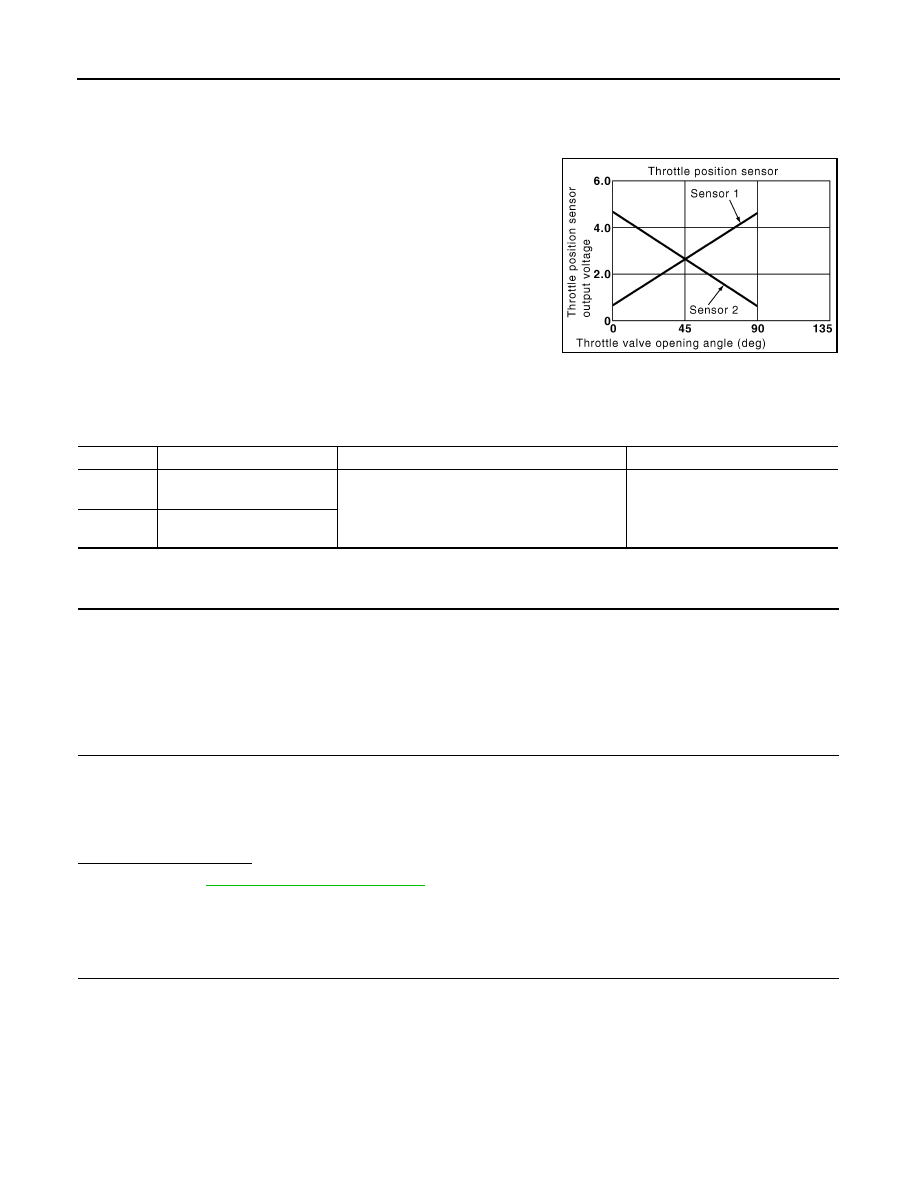

Electric throttle control actuator consists of throttle control motor,

throttle position sensor, etc. The throttle position sensor responds to

the throttle valve movement.

The throttle position sensor has two sensors. These sensors are a

kind of potentiometers which transform the throttle valve position into

output voltage, and emit the voltage signal to the ECM. In addition,

these sensors detect the opening and closing speed of the throttle

valve and feed the voltage signals to the ECM. The ECM judges the

current opening angle of the throttle valve from these signals and the

ECM controls the throttle control motor to make the throttle valve

opening angle properly in response to driving condition.

DTC Logic

INFOID:0000000003133518

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10 V at idle.

>> GO TO 2.

2.

PERFORM DTC CONFIRMATION PROCEDURE

1.

Turn ignition switch ON.

2.

Turn ignition switch OFF and wait at least 10 seconds.

3.

Turn ignition switch ON.

4.

Repeat steps 2 and 3 for 32 times.

5.

Check 1st trip DTC.

Is 1st trip DTC detected?

YES

>> Go to

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000003133519

1.

CHECK ELECTRIC THROTTLE CONTROL ACTUATOR VISUALLY

1.

Turn ignition switch OFF.

2.

Remove the intake air duct.

PBIB0145E

DTC No.

Trouble diagnosis name

DTC detecting condition

Possible cause

P1226

Closed throttle position learn-

ing performance (bank 1)

Closed throttle position learning is not performed

successfully, repeatedly.

• Electric throttle control actuator

(TP sensor 1 and 2)

P1235

Closed throttle position learn-

ing performance (bank 2)