Infiniti EX35. Manual - part 637

EC-290

< COMPONENT DIAGNOSIS >

[VQ35HR]

P0448 EVAP CANISTER VENT CONTROL VALVE

P0448 EVAP CANISTER VENT CONTROL VALVE

Description

INFOID:0000000003133440

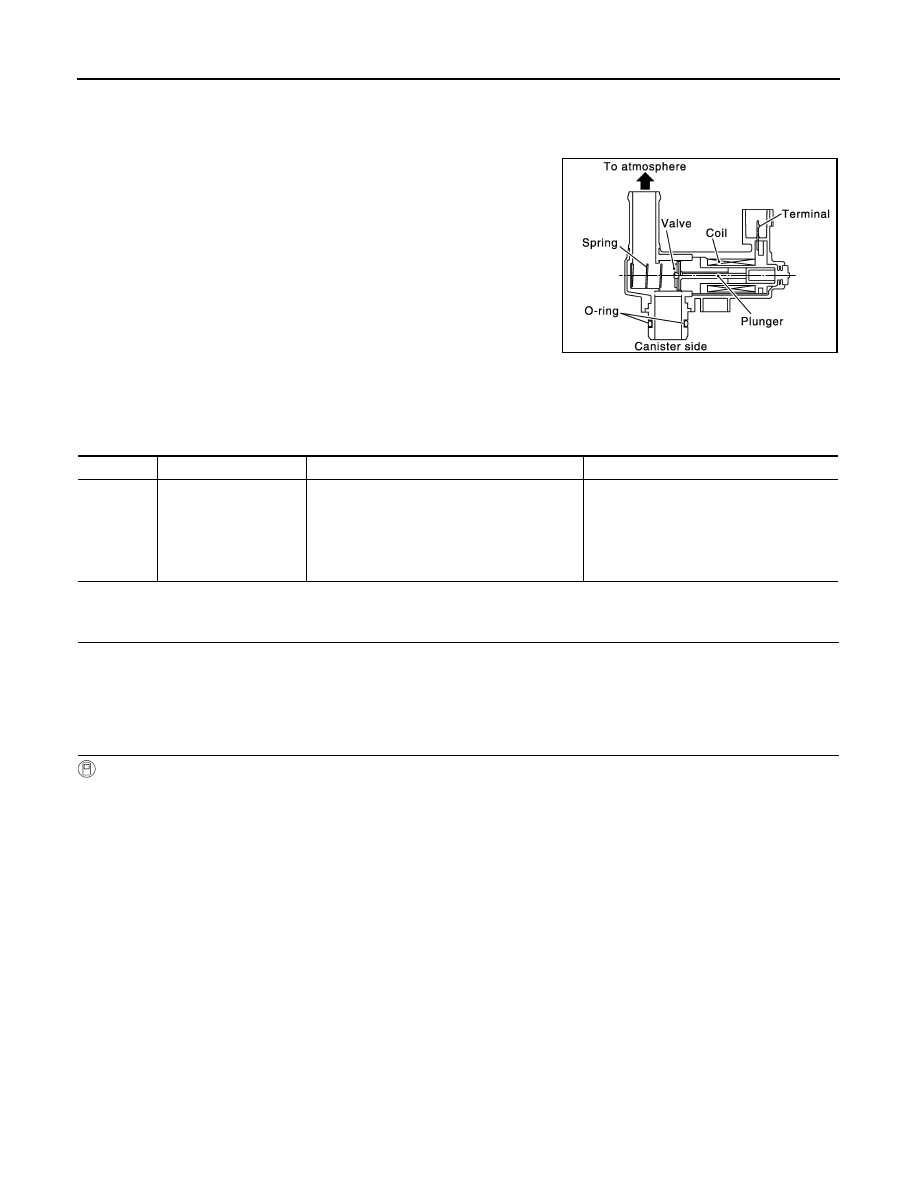

The EVAP canister vent control valve is located on the EVAP canis-

ter and is used to seal the canister vent.

This solenoid valve responds to signals from the ECM. When the

ECM sends an ON signal, the coil in the solenoid valve is energized.

A plunger will then move to seal the canister vent. The ability to seal

the vent is necessary for the on board diagnosis of other evaporative

emission control system components.

This solenoid valve is used only for diagnosis, and usually remains

opened.

When the vent is closed, under normal purge conditions, the evapo-

rative emission control system is depressurized and allows “EVAP

Control System” diagnosis.

DTC Logic

INFOID:0000000003133441

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

>> GO TO 2.

2.

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT-III

1.

Turn ignition switch ON and wait at least 5 seconds.

2.

Turn ignition switch OFF and wait at least 10 seconds.

3.

Turn ignition switch ON and select “DATA MONITOR” mode with CONSULT-III.

4.

Start engine and let it idle for at least 1 minute.

5.

Repeat next procedures three times.

-

Increase the engine speed up to 3,000 to 3,500 rpm and keep it for 2 minutes and 50 seconds to 3 min-

utes.

Never exceed 3 minutes.

-

Fully released accelerator pedal and keep engine idle for about 5 seconds.

6.

Repeat next procedure 20 times.

-

Quickly increase the engine speed up to 4,000 to 4,500 rpm or more and keep it for 25 to 30 seconds.

PBIB1263E

DTC No.

Trouble diagnosis name

DTC detecting condition

Possible cause

P0448

EVAP canister vent con-

trol valve close

EVAP canister vent control valve remains

closed under specified driving conditions.

• EVAP canister vent control valve

• EVAP control system pressure sensor

and the circuit

• Blocked rubber tube to EVAP canister

vent control valve

• EVAP canister is saturated with water