Infiniti EX35. Manual - part 550

DLN-150

< ON-VEHICLE REPAIR >

[REAR FINAL DRIVE: R200]

FRONT OIL SEAL

AWD : Removal and Installation

INFOID:0000000003135822

REMOVAL

CAUTION:

Verify identification stamp of replacement frequency put in the lower part of gear carrier to determine

replacement for collapsible spacer when replacing front oil seal. Refer to “Identification stamp of

replacement frequency of front oil seal”. If collapsible spacer replacement is necessary, remove final

drive assembly and disassemble it to replace front oil seal and collapsible spacer. Refer to

"AWD : Removal and Installation"

and

NOTE:

The reuse of collapsible spacer is prohibited in principle. However, it is reusable on a one-time basis

only in cases when replacing front oil seal.

Identification stamp of replacement frequency of front oil seal

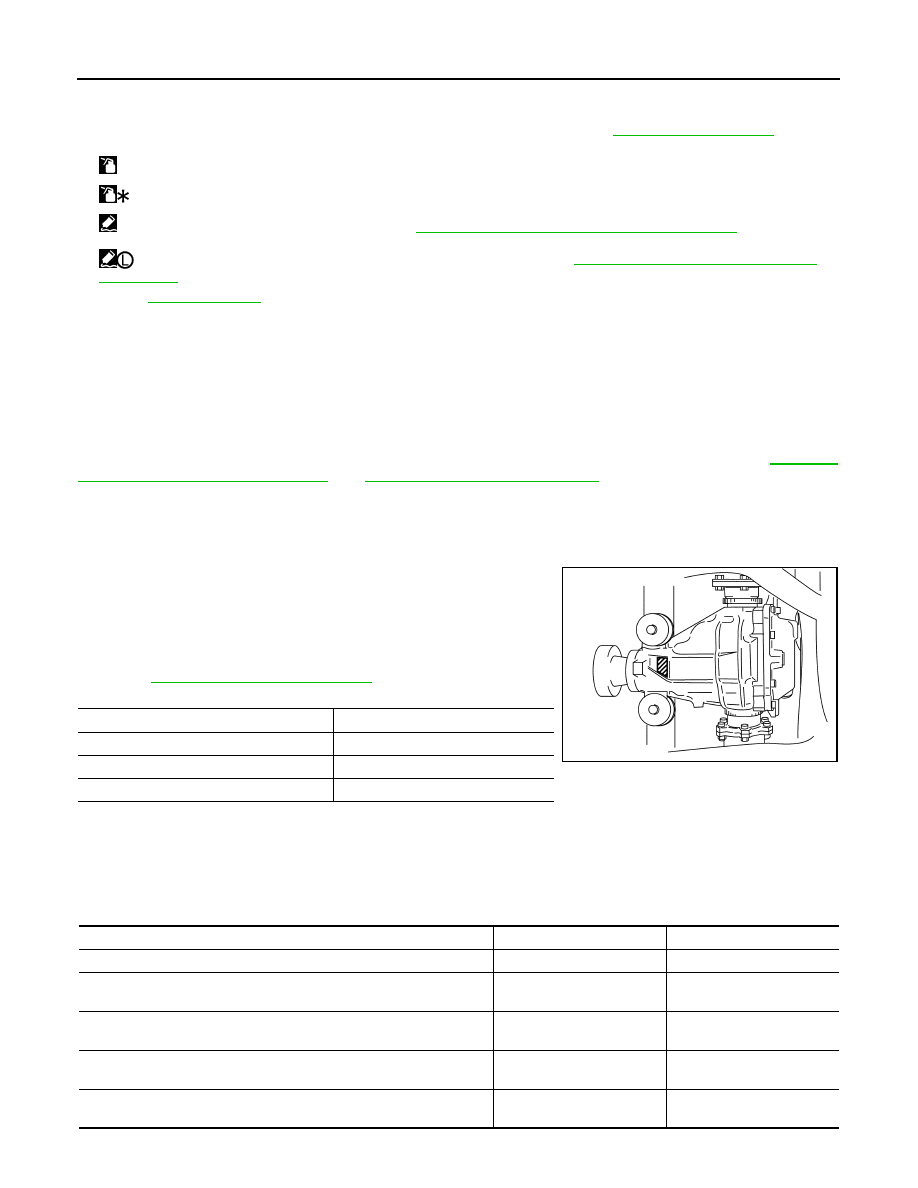

• The diagonally shaded area in the figure shows stamping point for

replacement frequency of front oil seal.

• The following table shows if collapsible spacer replacement is

needed before replacing front oil seal.

When collapsible spacer replacement is required, disassemble

final drive assembly to replace collapsible spacer and front oil seal.

Refer to

.

CAUTION:

Make a stamping after replacing front oil seal.

• After replacing front oil seal, make a stamping on the stamping point in accordance with the table below in

order to identify replacement frequency.

CAUTION:

Make a stamping from left to right.

25. Gasket

26. Rear cover

27. Drain plug

A.

Oil seal lip

B.

Screw hole

C.

For the tightening torque, refer to

.

: Apply gear oil.

: Apply anti-corrosion oil.

: Apply Genuine Silicone RTV or equivalent. Refer to

GI-15, "Recommended Chemical Products and Sealants"

.

: Apply Genuine High Strength Thread Locking Sealant or equivalent. Refer to

GI-15, "Recommended Chemical Products

Refer to

for symbols not described above.

Stamp

collapsible spacer replacement

No stamp

Not required

“0” or “0” on the far right of stamp

Required

“01” or “1” on the far right of stamp

Not required

PDIA0976E

Stamp before stamping

Stamping on the far right

Stamping

No stamp

0

0

“0”

(Front oil seal was replaced once.)

1

01

“01”

(Collapsible spacer and front oil seal were replaced last time.)

0

010

“0” is on the far right.

(Only front oil seal was replaced last time.)

1

...01

“1” is on the far right.

(Collapsible spacer and front oil seal were replaced last time.)

0

...010