Infiniti EX35. Manual - part 544

DLN-126

< DISASSEMBLY AND ASSEMBLY >

[FRONT FINAL DRIVE: F160A]

DRIVE PINION

Disassembly

INFOID:0000000003135801

1.

Remove differential case assembly. Refer to

2.

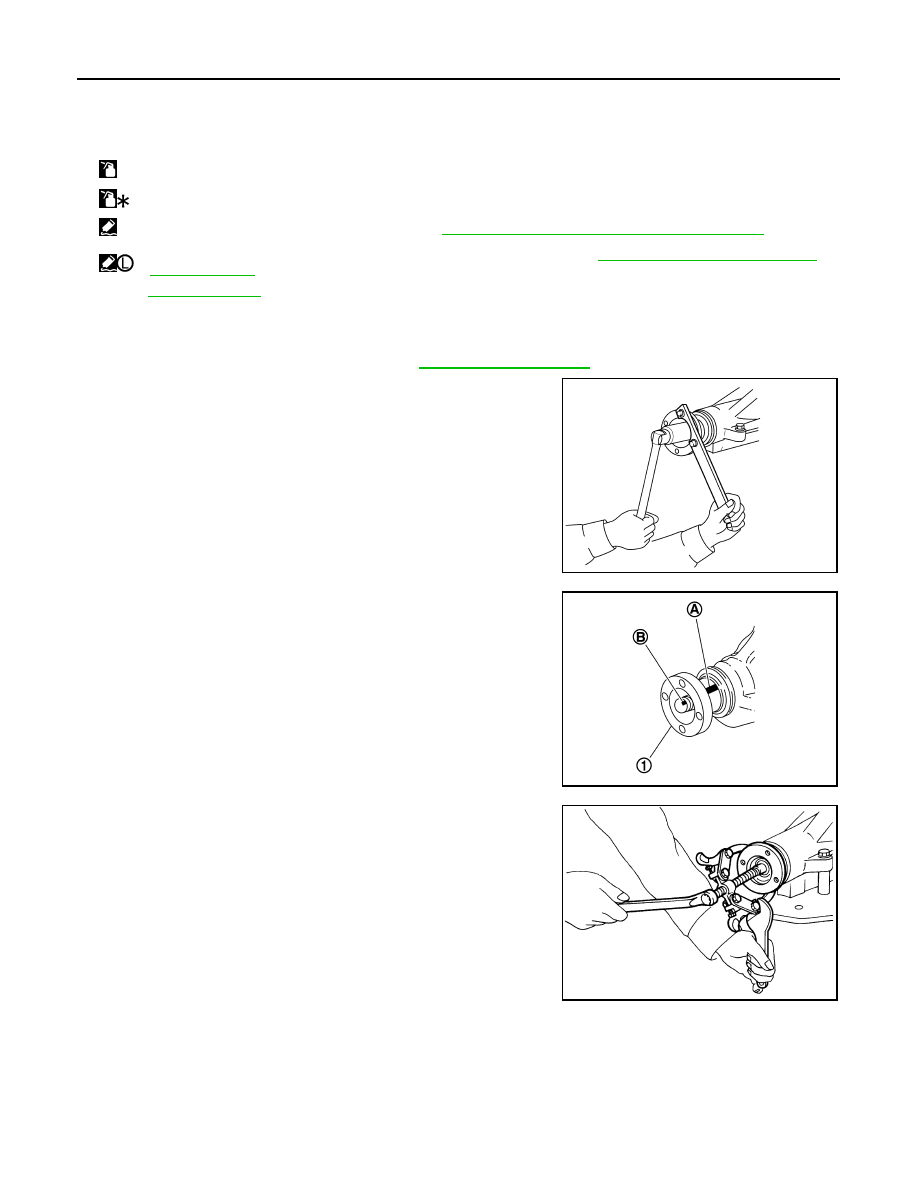

Remove drive pinion lock nut with a flange wrench.

3.

Put matching mark (B) on the end of drive pinion. The matching

mark should be in line with the matching mark (A) on companion

flange (1).

CAUTION:

For matching mark, use paint. Never damage companion

flange and drive pinion.

NOTE:

The matching mark (A) on the final drive companion flange (1)

indicates the maximum vertical runout position.

When replacing companion flange, matching mark is not neces-

sary.

4.

Remove companion flange using the suitable puller.

34. Side shaft bearing

35. Extension tube retainer

36. Side shaft oil seal

37. Dust seal

38. Side shaft

A:

Oil seal lip

B:

Screw hole

:

Apply gear oil.

:

Apply anti-corrosion oil.

:

Apply Genuine Silicone RTV or equivalent. Refer to

GI-15, "Recommended Chemical Products and Sealants"

:

Apply Genuine Medium Strength Thread Locking Sealant or equivalent. Refer to

GI-15, "Recommended Chemical Prod-

.

Refer to

for symbols not described above.

PDIA0798J

PDIA0799J

SDIA1132E