Infiniti EX35. Manual - part 541

DLN-114

< DISASSEMBLY AND ASSEMBLY >

[FRONT FINAL DRIVE: F160A]

DIFFERENTIAL ASSEMBLY

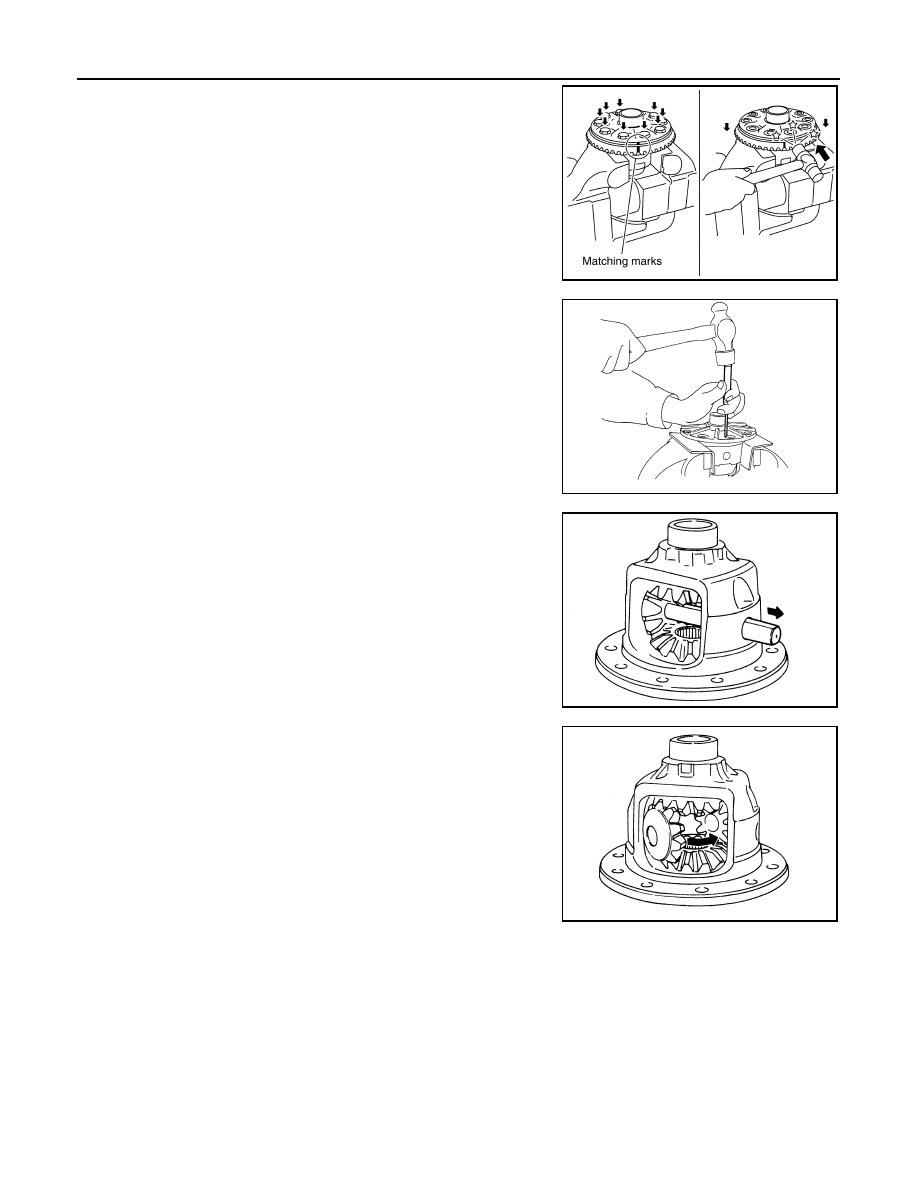

14. For proper reinstallation, paint matching marks on one differen-

tial case assembly.

CAUTION:

For matching marks, use paint. Never damage differential

case and drive gear.

15. Remove drive gear mounting bolts.

16. Tap drive gear off differential case assembly with a soft hammer.

CAUTION:

Tap evenly all around to keep drive gear from bending.

17. Remove lock pin of pinion mate shaft with a punch from drive

gear side.

18. Remove pinion mate shaft.

19. Turn pinion mate gear, then remove pinion mate gears, pinion

mate thrust washers, side gears and side gear thrust washers

from differential case.

PDIA0496E

PDIA0759J

SDIA0031J

SDIA0032J