Infiniti EX35. Manual - part 331

C1105, C1106, C1107, C1108 WHEEL SENSOR

BRC-39

< COMPONENT DIAGNOSIS >

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

M

A

B

BRC

N

O

P

4.

Check terminal to see if it is deformed, disconnected, looseness, etc.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair or replace damaged parts.

4.

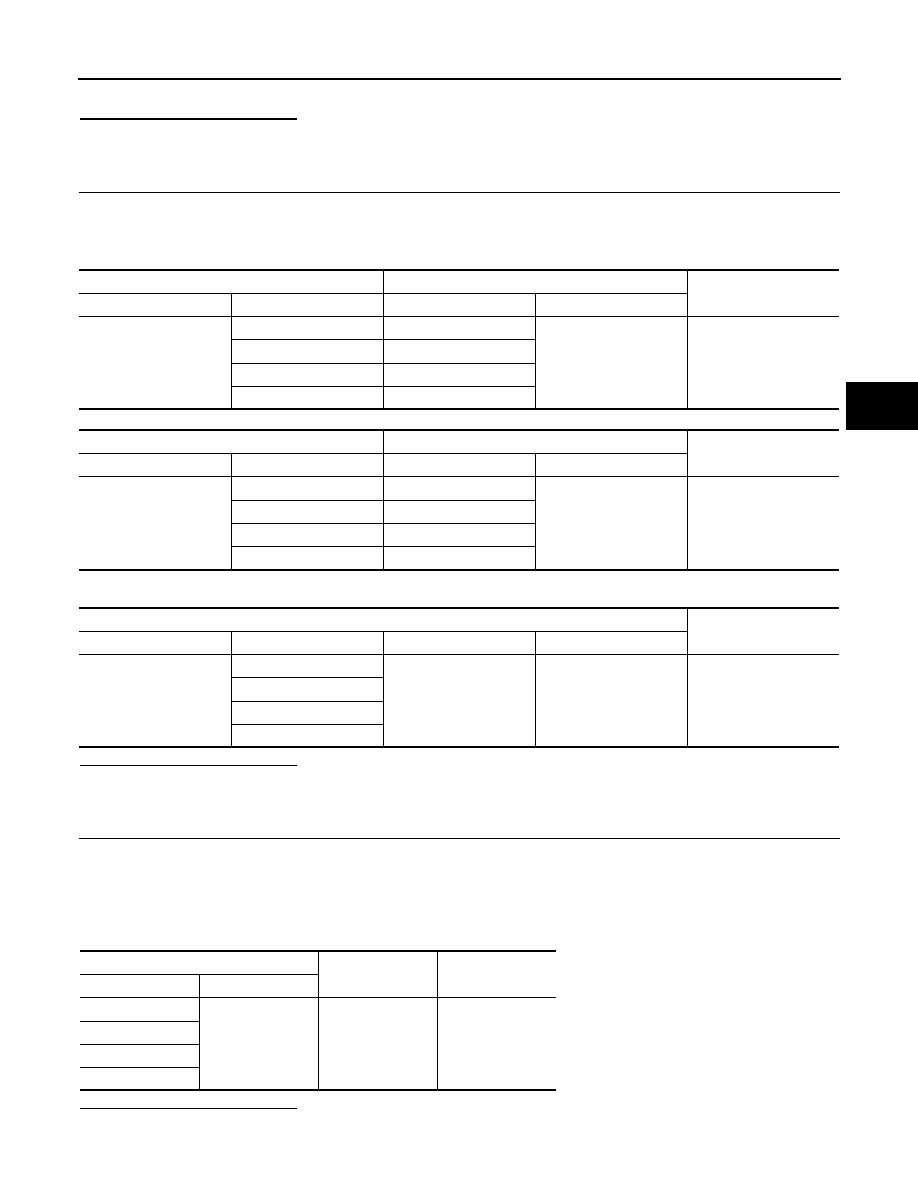

CHECK WHEEL SENSOR HARNESS

1.

Check the continuity between ABS actuator and electric unit (control unit) harness connector and wheel

sensor harness connector. (Also check continuity when steering wheel is turned right and left and when

sensor harness inside the wheel house is moved.)

Measurement terminal for power supply circuit

Measurement terminal for signal circuit

2.

Check the continuity between ABS actuator and electric unit (control unit) harness connector.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Repair or replace damaged parts.

5.

CHECK WHEEL SENSOR POWER SUPPLY CIRCUIT

1.

Connect ABS actuator and electric unit (control unit) connector.

2.

Turn the ignition switch ON.

CAUTION:

Never start the engine.

3.

Check the voltage between wheel sensor harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 6.

ABS actuator and electric unit (control unit)

Wheel sensor

Continuity

Connector

Terminal

Connector

Terminal

E41

9

E27 (Front RH)

1

Existed

26

E60 (Front LH)

7

B33 (Rear RH)

6

B34 (Rear LH)

ABS actuator and electric unit (control unit)

Wheel sensor

Continuity

Connector

Terminal

Connector

Terminal

E41

10

E27 (Front RH)

2

Existed

5

E60 (Front LH)

29

B33 (Rear RH)

27

B34 (Rear LH)

ABS actuator and electric unit (control unit)

Continuity

Connector

Terminal

Connector

Terminal

E41

9, 10

E41

1, 4

Not existed

26, 5

7, 29

6, 27

Wheel sensor

—

Voltage

Connector

Terminal

E27 (Front RH)

1

Ground

8 V or more

E60 (Front LH)

B33 (Rear RH)

B34 (Rear LH)