Content .. 1519 1520 1521 1522 ..

Infiniti EX35. Manual - part 1521

WT-40

< COMPONENT DIAGNOSIS >

TIRE PRESSURE WARNING CHECK SWITCH

YES

>> Repair or replace BCM circuit. Replace BCM. Refer to

BCS-84, "Removal and Installation"

.

NO

>> GO TO 2.

2.

CHECK TIRE PRESSURE WARNING CHECK SWITCH CIRCUIT

1.

Turn the ignition switch OFF.

2.

Disconnect BCM harness connector

3.

Check continuity between BCM harness connector and tire pressure warning check switch connector.

4.

Check continuity between BCM harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Repair or replace damaged parts.

3.

CHECK BCM

Check BCM input/output signal. Refer to

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Check BCM pin terminals for damage or loose connection with harness connector. If any items

are damaged, repair or replace damaged parts. Replace BCM. Refer to

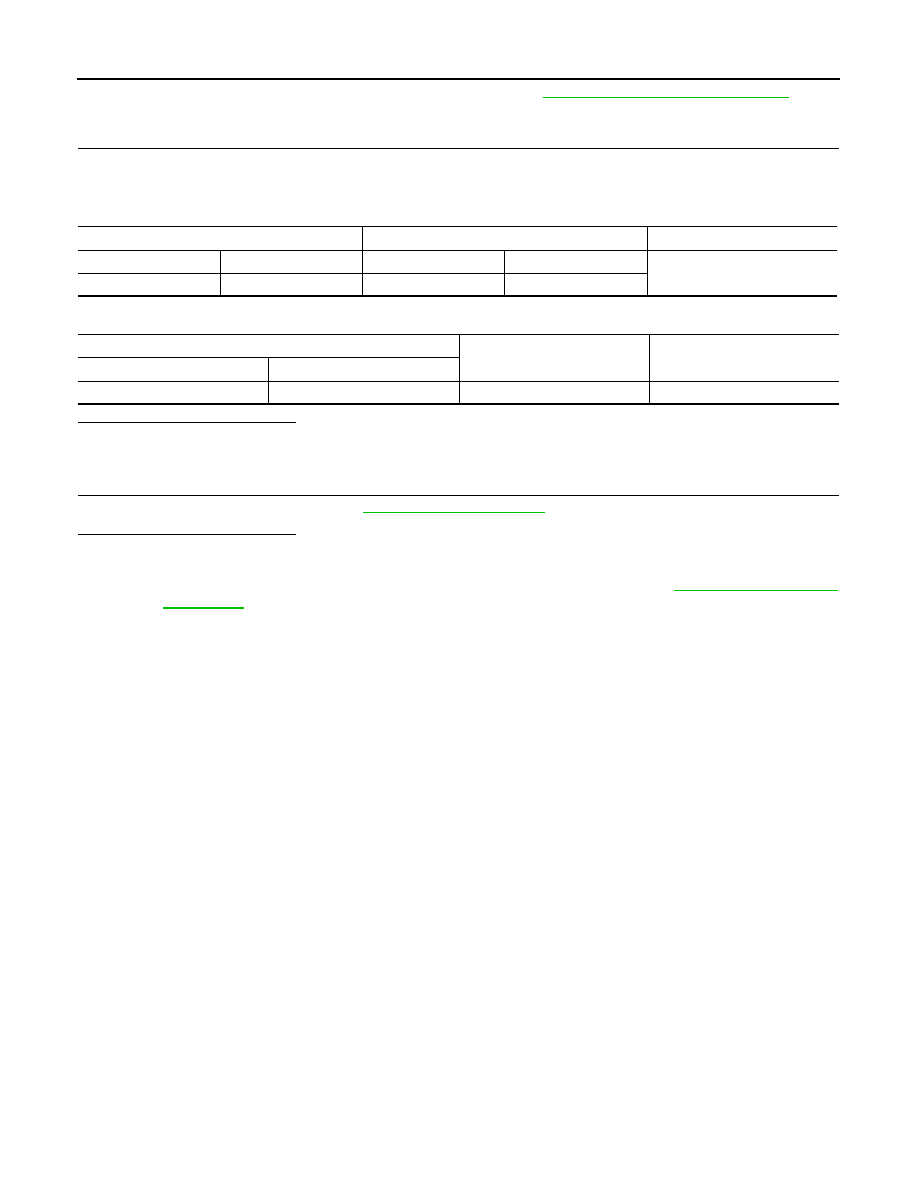

BCM

Tire pressure warning check switch

Continuity

Connector

Terminal

Connector

Terminal

Existed

M123

149

M23

1

BCM

—

Continuity

Connector

Terminal

M123

149

Ground

Not existed