Content .. 1055 1056 1057 1058 ..

Infiniti EX35. Manual - part 1057

MA-18

< ON-VEHICLE MAINTENANCE >

ENGINE MAINTENANCE

2.

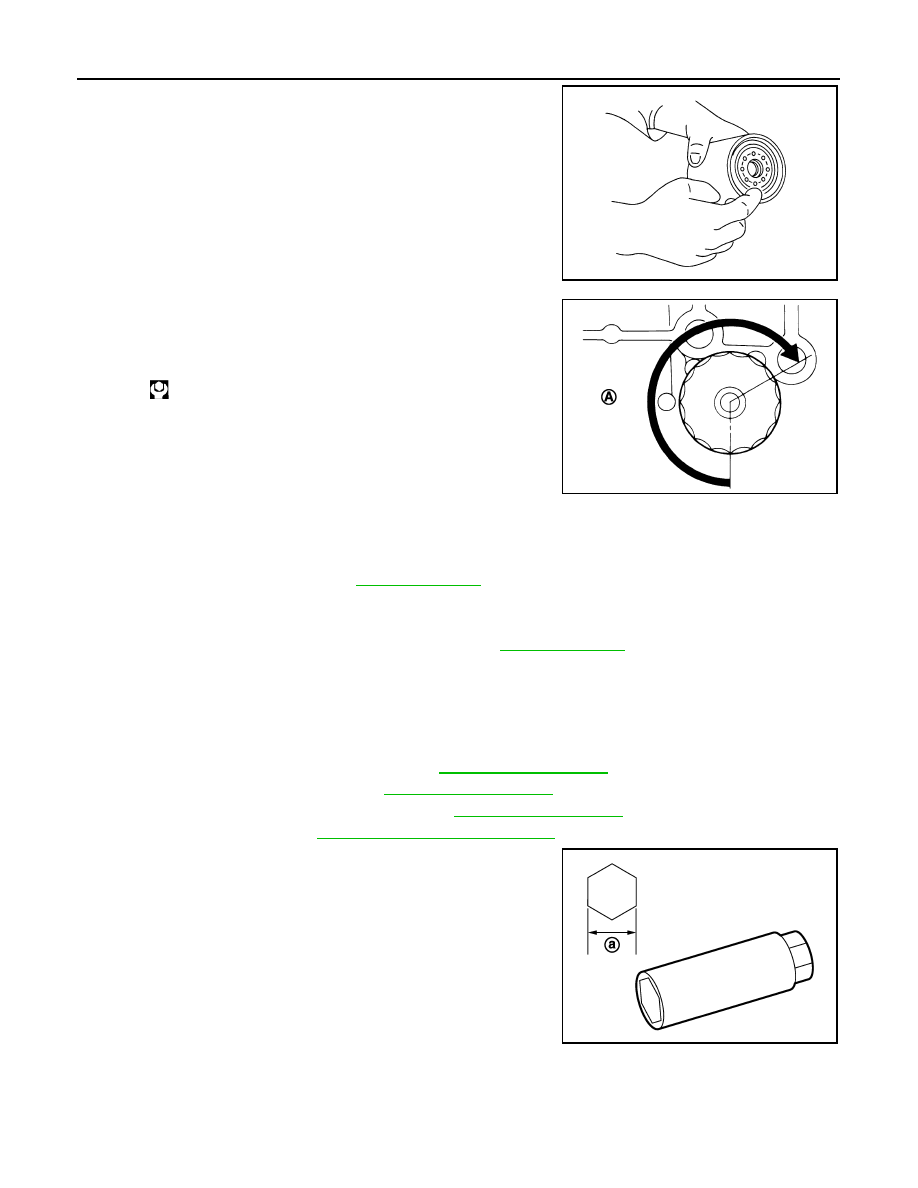

Apply engine oil to the oil seal contact surface of new oil filter.

3.

Screw oil filter manually until it touches the installation surface,

then tighten it by 2/3 turn (A). Or tighten to the specification.

OIL FILTER : Inspection

INFOID:0000000003556583

INSPECTION AFTER INSTALLATION

1.

Check the engine oil level. Refer to

.

2.

Start the engine, and check there is no leakage of engine oil.

3.

Stop the engine and wait for 10 minutes.

4.

Check the engine oil level, and adjust the level. Refer to

.

SPARK PLUG

SPARK PLUG : Removal and Installation

INFOID:0000000003556584

REMOVAL

1.

Remove engine cover with power tool. Refer to

.

2.

Remove air duct (RH and LH). Refer to

.

3.

Remove electric throttle control actuator. Refer to

.

4.

Remove ignition coil. Refer to

EM-47, "Removal and Installation"

.

5.

Remove spark plug with a spark plug wrench (commercial ser-

vice tool).

INSTALLATION

Installation is the reverse order of removal.

SMA010

Oil filter:

: 17.7 N·m (1.8 kg-m, 13 ft-lb)

JPBIA0077ZZ

a

: 14 mm (0.55 in)

JPBIA0030ZZ