Content .. 1050 1051 1052 1053 ..

Infiniti EX35. Manual - part 1052

LU-14

< DISASSEMBLY AND ASSEMBLY >

OIL PUMP

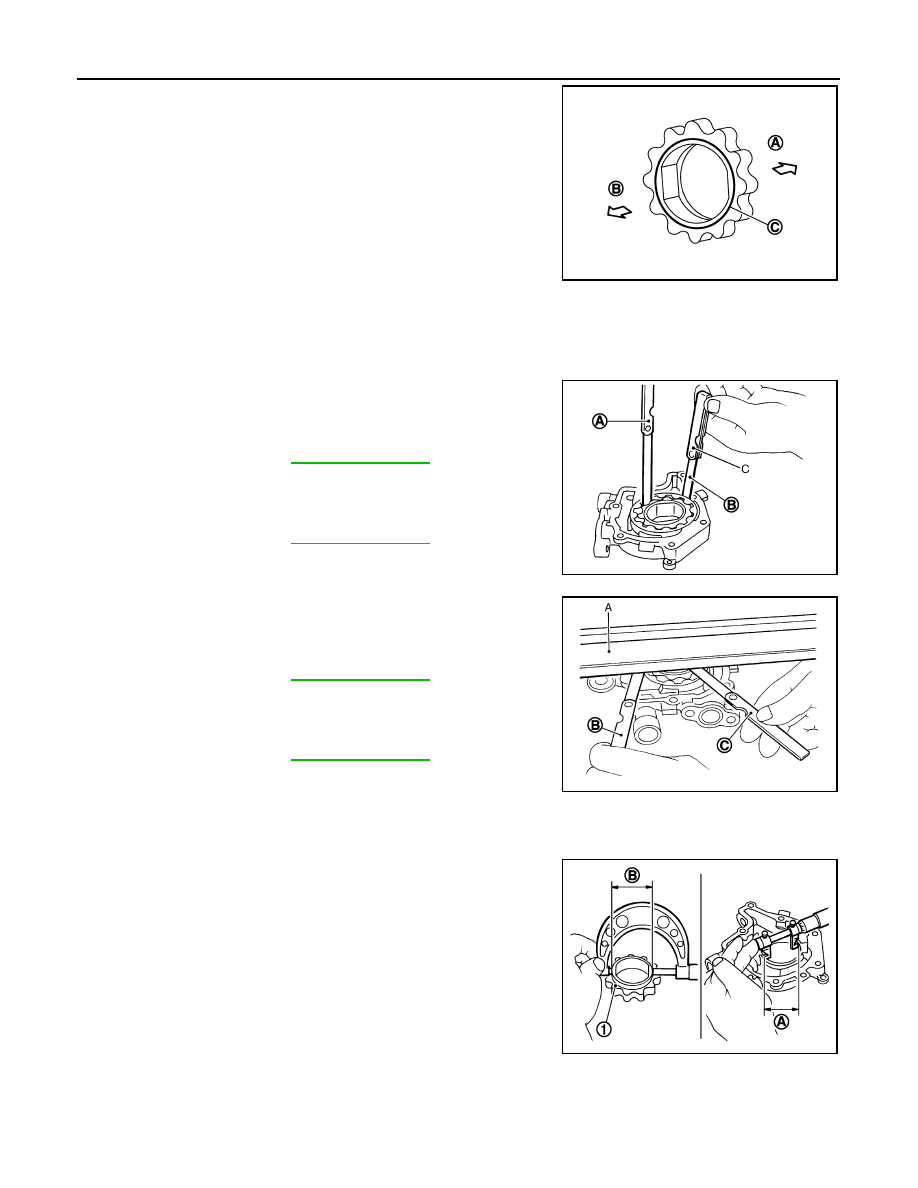

• Install oil pump inner rotor with the groove faced to oil pump cover

side.

• When installing oil pump, align crankshaft flat faces with oil pump

inner rotor flat faces.

Inspection

INFOID:0000000003134541

INSPECTION AFTER DISASSEMBLY

Oil Pump Clearance

• Measure the clearance with feeler gauge (C).

- Clearance between oil pump outer rotor and oil pump body [posi-

tion (B)]

- Tip clearance between oil pump inner rotor and oil pump outer

rotor [position (A)]

• Measure the clearance with feeler gauge and straightedge (A).

- Side clearance between oil pump inner rotor and oil pump body

[position (C)]

- Side clearance between oil pump outer rotor and oil pump body

[position (B)]

• Calculate the clearance between oil pump inner rotor and oil pump body as follows:

OIL PUMP BODY INNER DIAMETER

- Measure the inner diameter of oil pump body with inside microme-

ter. [position (A)]

OIL PUMP INNER ROTOR OUTER DIAMETER

- Measure the outer diameter of protruded portion of oil pump inner

rotor (1) with micrometer. [position (B)]

OIL PUMP INNER ROTOR TO OIL PUMP BODY CLEARANCE

- (Clearance) = (Oil pump body inner diameter) – (Oil pump inner rotor outer diameter)

A

: Oil pump body side

B

: Oil pump cover side

C

: Groove

JPBIA0084ZZ

Standard

: Refer to

.

Standard

: Refer to

.

JPBIA0078ZZ

Standard

: Refer to

.

Standard

: Refer to

.

JPBIA0079ZZ

JPBIA0080ZZ