Honda Element. Manual - part 472

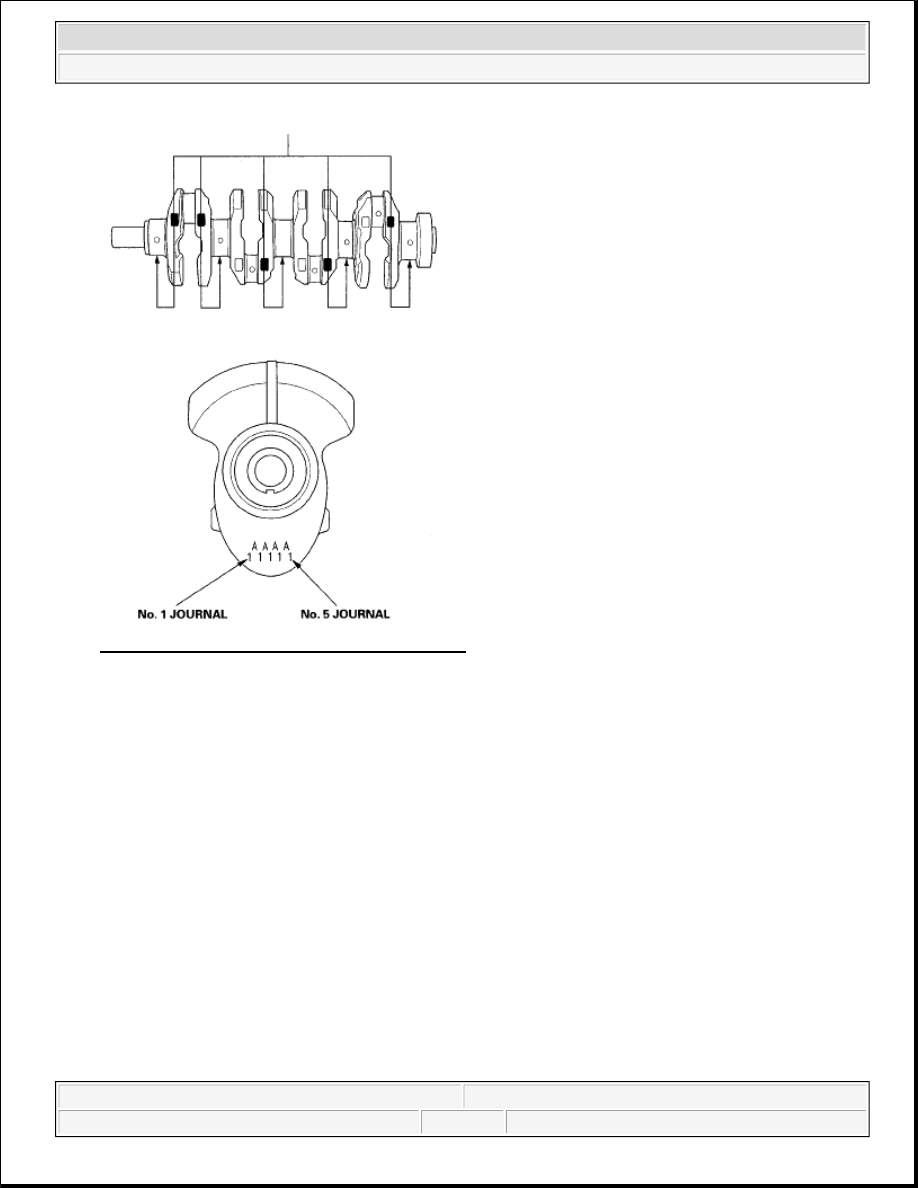

Fig. 9: Identifying Main Journal Code Location

Courtesy of AMERICAN HONDA MOTOR CO., INC.

3. Use the crank bore codes and crank journal codes to select the appropriate replacement bearings from the

following table.

NOTE:

The color code is on the edge of the bearing.

When using bearing halves of different colors, it does not matter

which color is used in the top or bottom.

2007 Honda Element EX

2007-08 ENGINE Engine Block - Element