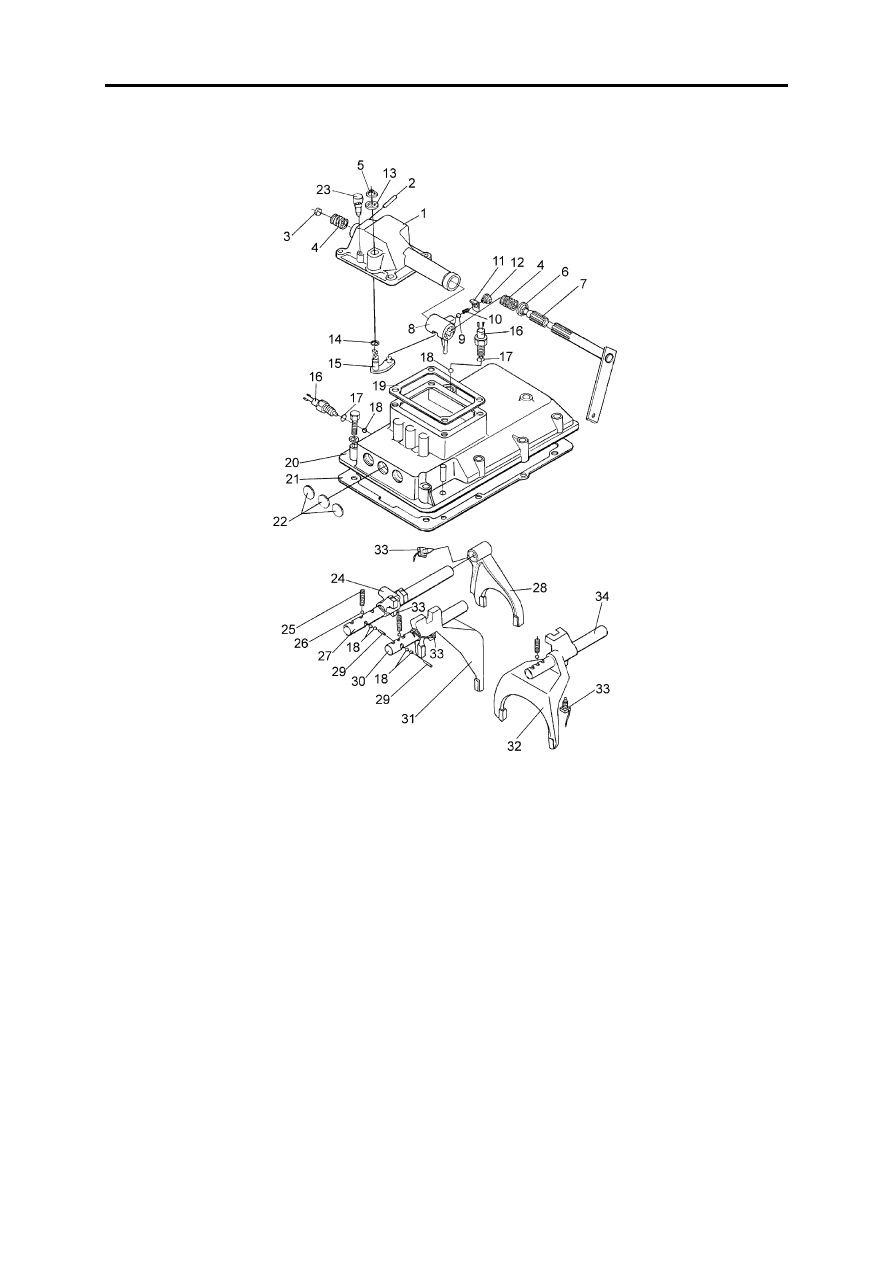

Dongfeng DFA1063DJ10 (14)-301/303. Manual - part 8

Transmission

MT-7

Transmission cover

1.Cover

2.Straight pin

3.Bell cap

4.Balancing spring--selecting shaft

5.Circlip for shaft

6.Oil seal--transmission cover

7.Control shaft and gear shift arm assy

8.Transmission shift lever

9.Steel ball

10.Damping spring--reverse gear

11.Lock shim--spring seat

12.Damping spring seat--reverse gear

13.Washer

14.O-ring

15.Gear selecting rotating arm assy

16.Switch assy

17.Sealing ring

18.Steel ball

19.Gasket spacer--cover

20.Transmission upper cover

21.Gasket spacer--upper cover

22.Spacer

23.Vent plug assy

24.Guide block--1st, reverse gear

25.Locking gear shift fork shaft spring

26.Steel ball

27.Gear shift fork shaft --1st, reverse gear

28.Gear shift fork --1st, reverse gear

29.Straight pin--interlock

30.Gear shift fork shaft--2nd, 3rd gear

31.Gear shift fork--2nd, 3rd gear

32.Gear shift fork--4th, 5th gear

33.Locking bolt--gear shift fork

34.Gear shift fork shaft--4th, 5th gear