Dongfeng EQ1030T47D-820. Manual - part 42

Electric System

EL-2

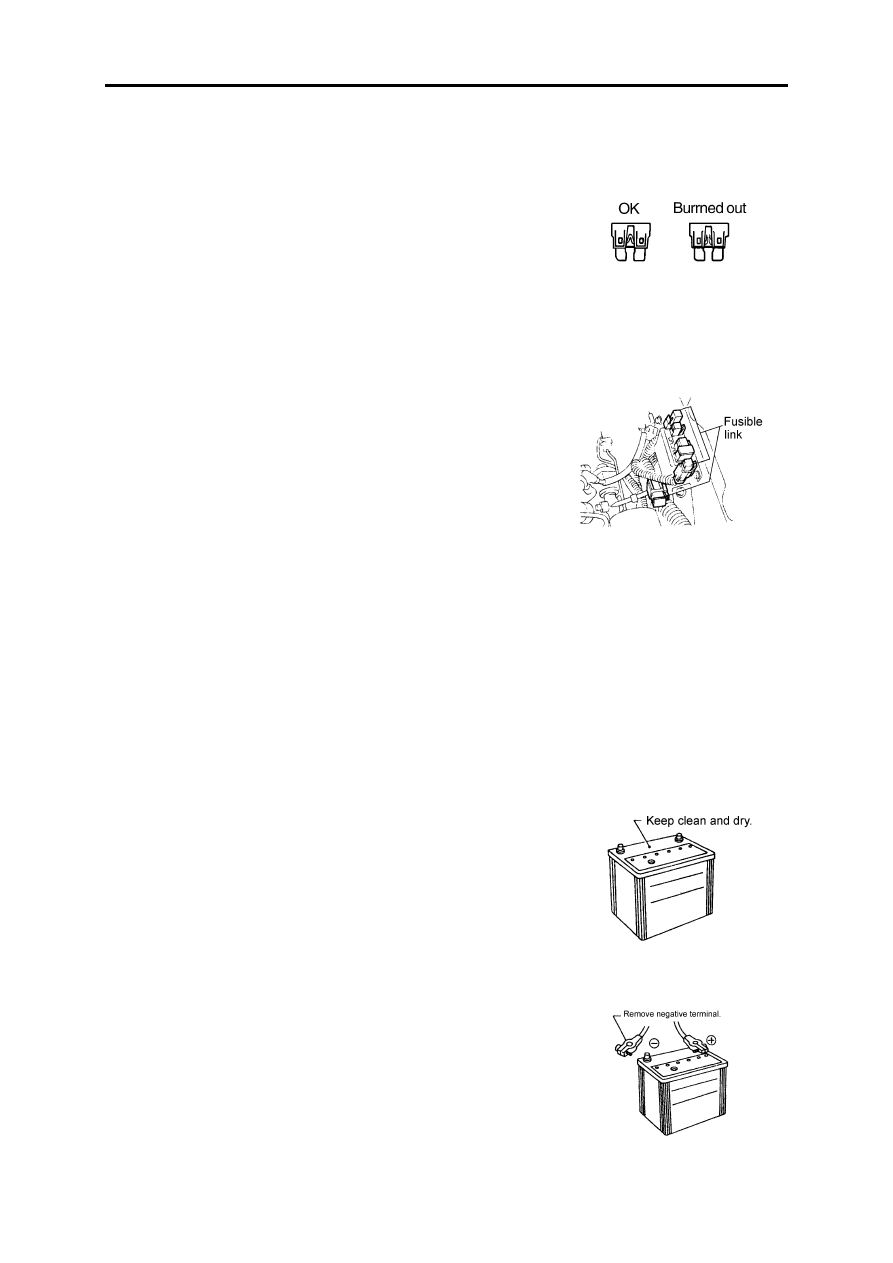

Fuse Wire and Fusible Link

Fuse wire

If the fuse wire is broken,the problem must be solved before replac-

ing the fuse wire.

Use proper fuse,do not use the fuse with much higher than rated

value.

Insert the fuse box correctly,do not slope it.

Take off the fuse wire of the clock,if the vehicle is not used for long

time.

Fusible link

The melted fusible link can be seen with eyes,if not sure,check it with

a electric measuring device and a check lamp.

Note:

If the fusible link is melted,maybe the key circuit breaks down(power line

or big electric flow circuit).Under such condition,carefully check and

solve the problems.

Battery

Caution

:

Start the engine with supporting battery and the cable if necessary

.please use 12 V auxiliary battery.

After connecting the battery cable, make sure their connection with

the joints is well.

How to maintain the battery

Method of preventing over-discharge

The following precautions must be taken to prevent the battery over-

discharge.

1.The battery surface(partticularly its top)should always be kept clean

and dry.

If there is electrolyte or water on the top, it will cause the battery to

discharge.

2.If the vehicle no used for quite long time, release off the negative pole

joint.