Dongfeng EQ1030T47D-820. Manual - part 16

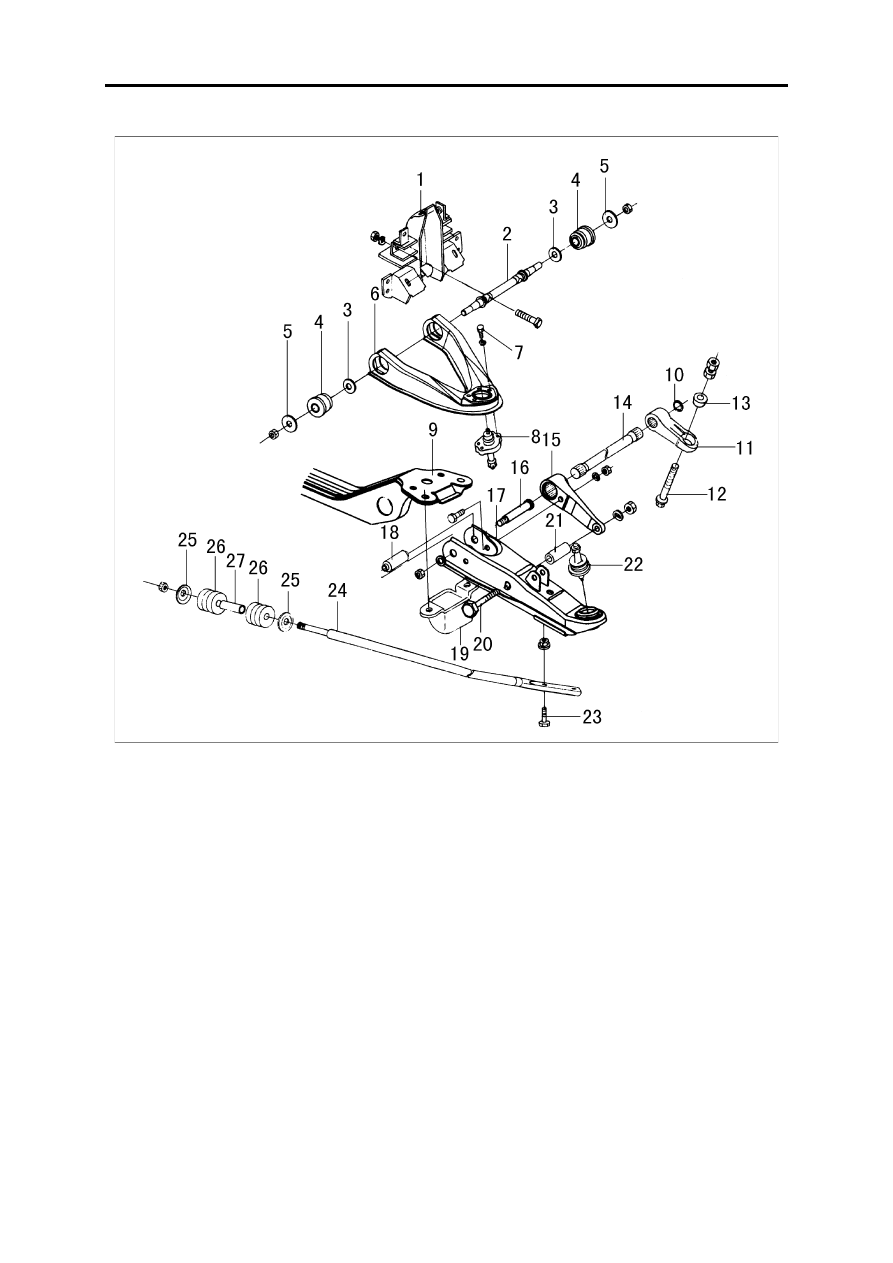

Front suspension

FA-16

Front Independent Suspension

When assembling the rubber part, the final tightening has to be under such condition: wheel on the ground,

no load.

Condition of no load: with full fuel, coolant, engine lubricant, and the spare tyre, jack, driver tool on the

vehicle, and the vehicle park on the level position.

1.

Shock absorber assy

2.

Upper arm shaft

3.

Inner side washer

4.

Rubber bush assy

5.

Big washer

6.

Upper transverse arm

7.

Bolt

8.

Round head pin assy

9.

Front suspension cross member assy

10.

Circlip for holes

11.

Torsion bar adjusting arm

12.

Adjust bolt

13.

Round head

14.

Front torsion bar spring

15.

Torsion bar fixing bar

16.

Lower arm shaft

17.

Lower transverse arm assy

18.

Rubber bush assy

19.

Limit block assy

20.

Bolt

21.

Rubber bush assy

22.

Round head pin assy

23.

Bolt

24.

Propelling rod

25.

Big washer

26.

Rubber bush

27.

Spacer sleeve