Dongfeng EQ1030T47D-820. Manual - part 4

General

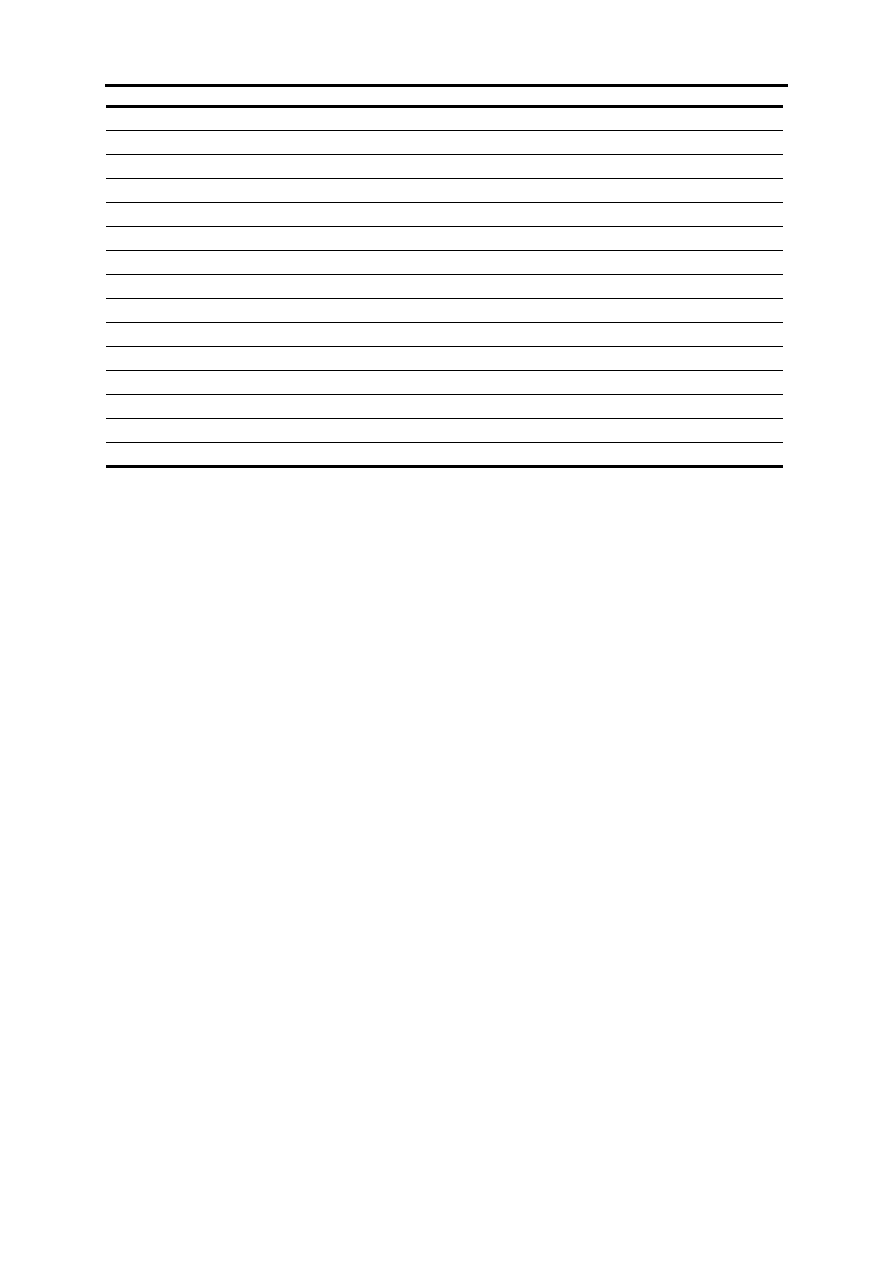

GL-12

As for the other torques not mentioned, please see the standard of DONGFENG EQB-37-1999.

Note:

No locking spacer, but to make sure the required tightening torque.

When tightening during installing, make use of the oil to lubricate. Do not use the bolt with thread

damaged.

Each bolt need to tighten within 2~3 times.

Muffler fixed bolt

32~38

Battery frame and frame connecting part

35~47

Battery pressure lever fixed nut part

19~24

Front bumper and cross member connecting part

19~24

Power steering oil pipe joint nut

30~40

Air filter bracket and longitudinal connecting part

21~28

Power steering pump adjusting nut

25~31

Power steering pump adjusting bolt

19~25

Alternator adjusting lever bolt and nut

13~19

Push lever bolt of clutch master cylinder

8~11

Clutch pedal brake lock locking nut

12~15

Clutch pressure disc and flywheel fixed bolt

25~35

Fan fixed bolt

7~9

Push lever nut of brake thruster

16~22

Part

Tightening torque (N.m)