Dongfeng DFA1101GZ5AD6J-907. Manual - part 20

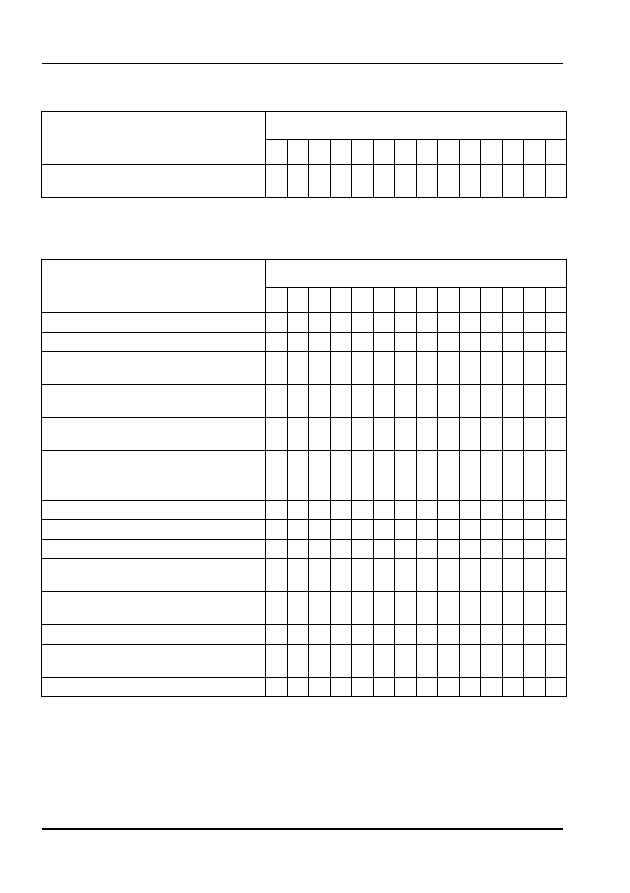

Maintenance Schedule

10—4

Check working condition of air

compressor

★

Steering System

Maintenance Items

Maintenance Intervals (× 1000km)

4 8 12 16 20 24 28 32 36 40 44 48 80

Check steering gear for oil leakage

☆ ★ ★ ★ ★ ★ ★ ★ ★ ★ ★ ★ ★

Clean steering gear

★ ★ ★ ★ ★ ★ ★ ★ ★ ★ ★ ★

Check steering wheel for free play

and operating

☆

★

★

★

★

Check tightening condition of tie rod

ends and drag link joints

☆

★

★

★

★

Check tightening condition of

steering mechanism and brackets

☆

★

★

★

★

Check tightening condition of

knuckle arm and pitman arm of the

steering

☆

★

★

★

★

Check and adjust toe-in

☆

★

★

★

★

Check front wheel alignment

★

Check and adjust steering gear

★

Dismantle and check tie rod ends

and drag line joints

★

Have a magnetic detection for

steering knuckle

★

Change steering ball joint pin

★

Check the oil level of the steering oil

reservoir

☆ ★ ★ ★ ★ ★ ★ ★ ★ ★ ★ ★ ★

Replace the steering drive shaft

★

★

Brake System

Maintenance Items

Maintenance Intervals (× 1000km)

4 8 12 16 20 24 28 32 36 40 44 48 80