Dongfeng DFA1101GZ5AD6J-907. Manual - part 18

General Adjustment

9—7

3.Screw on the bleeding bolt, trample

down the clutch pedal, then screw off

the bleeding bolt to exhaust the air in

the oil, then screw on again and

release the clutch pedal.

4.Do the 3rd step repeatedly until there

is no bubbles come out and you can

feel the clutch can be disengaged

totally.

Adjustment of Brake Clearance

In normal condition, the brake

clearance

is between 0.6mm~0.8mm.

After replace the brake shoe lining,

you must

have a completely adjustment to

the brake

, the method is as follows:

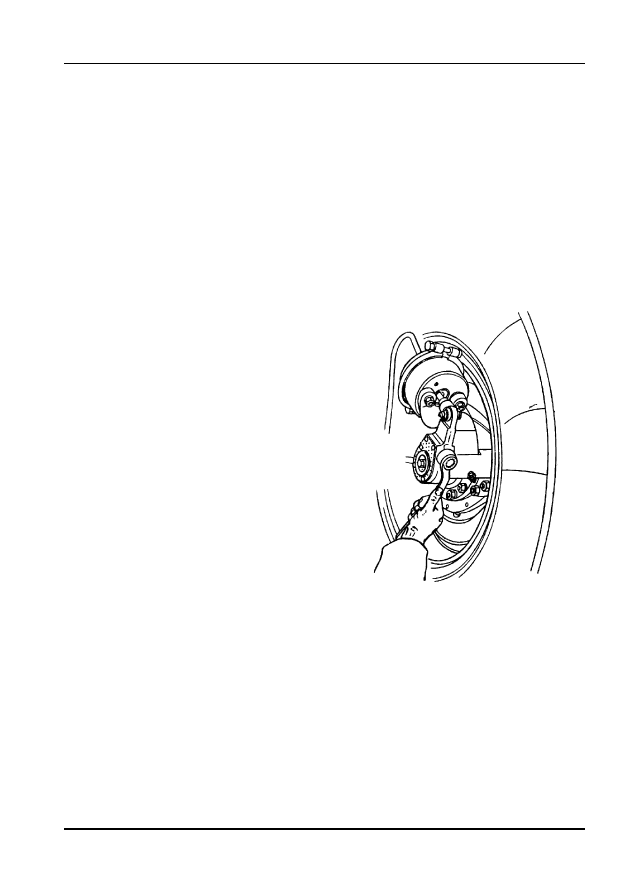

Use the wrench to first turn the

adjusting arm worm shaft to achieve

the full contact of the brake shoe

surface abd brake drum surface, then

turn it loose for 1/2~2/3 circle(at that

time the clearance between the center

of the fricton lining and the brake drum

is about 0.7mm), and the brake drum

hub assembly can turn freely without

any interface to other parts.

The spring brake chamber do not

need maintenance, but examine and

repair once after 2 years using.

Check: The starting pressure of the

diaphragm cylinder is 20~30kPa. If the

pressure rise to 50kPa, you have to

check it. Under the condition of wheel

brake in proper adjustment, the dia-

phram travel should be 1/3 of the possi-

ble total diaphram travel. At this time,