Saturn Transmission. Manual - part 17

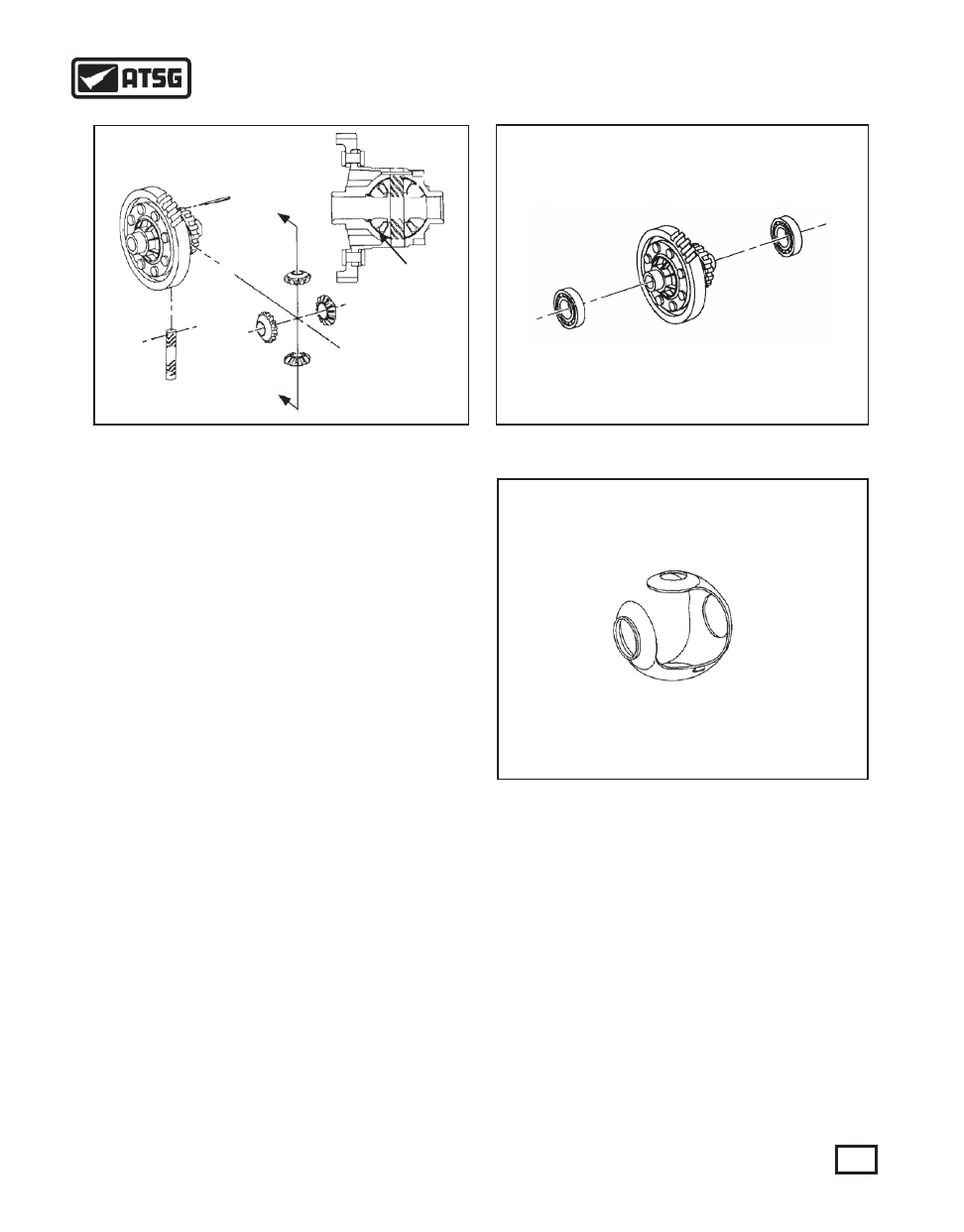

Figure 157

DIFFERENTIAL DISASSEMBLY

1. Using a suitable drift pin, drive the roll pin from

the differential housing and remove the pinion

shaft and side gears (See Figure 157).

2. Rotate the pinion gears and remove them from the

housing (See Figure 157).

3. Remove the plastic side gear liner from the

housing (See Figure 159).

4. Inspect the pinion shaft for wear, the side gears for

wear and the side gear liner for wear. Replace

if necessary.

5. Inspect the differential side bearings for wear and

pit marks and replace if necessary. To remove the

bearings, use a suitable puller (See Figure 158).

A) To remove the speed sensor side bearing, a

typical puller can be used.

B) To remove the differential gear side bearing,

use a two jaw puller. Place a shield over the

bearing to provide protection if the bearing

should break.

DIFFERENTIAL ASSEMBLY

1. NOTICE: The bearing on the right side (The

vehicle speed sensor side) of the differential has

a black colored cage. (Service bearings

however, will all have a black cage and are

interchangeable).

2. Press the new differential bearings onto the

differential housing using Saturn's tool SA9120T

or equivalent. Check to be sure that the bearings

are fully seated.

3. Install the side gear liner into the housing. Position

the liner inside the housing so that the side gear

section with the alignment tabs set into the pocket

on the ring gear side of the case.

Figure 158

SIDE GEAR

LINER

4. Place the side gears into position in the housing

and hold in position.

5. Install one of the pinion gears on the tabbed side

of the thrust liner and then pull the thrust liner

partially over the pinion gear to hold it into place.

6. Place the second pinion gear into position, directly

opposite from the first pinion gear. Rotate the

thrust liner until the pinion gear holes line up with

the shaft holes in the housing.

7. Install the side gears into the housing.

8. Install the pinion shaft and a new roll pin. Be sure

to drive the roll pin flush to the housing

preventing any interference with the speed sensor

signal.

9. Install the differential assembly into the converter

housing case half.

Figure 159

71

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information