Saturn Transmission. Manual - part 15

installer kit number is SA9143T. It consists of:

SA9144T-1 - The re-sizer

SA9144T-2 - Long expander

SA9144T-3 - Medium expander

SA9144T-4 - Short expander

20. After the rings are installed, use the seal sizer by

rotating the tool and pushing lightly onto one seal

at a time until all three rings have been re-sized

(See Figure 129).

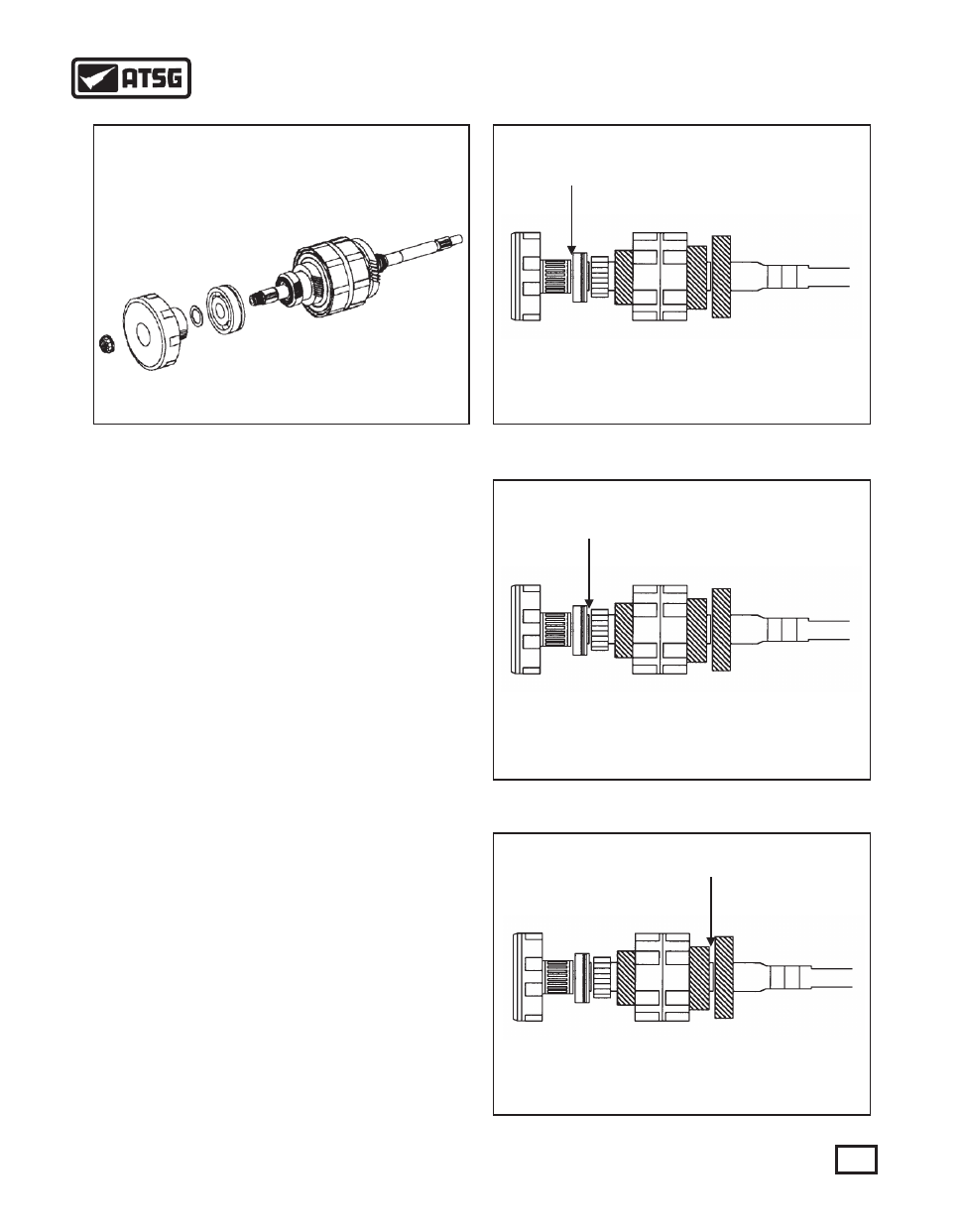

21. Install the input shaft bearing, 1st drive gear to

case thrust washer and 1st clutch housing assembly

onto the input shaft (See Figure 130).

22. Torque the end nut to 150 N m (111 ft lbs).

23. Using a feeler gauge, check the clearance between

the 1st drive gear and case bearing (See Figure

131). The clearance should be:

0.075 mm - 0.425 mm or

0.003 in. - 0.017 in.

24. Using a feeler gauge, check the clearance between

the 2nd/Rev drive gear and the 2nd/Rev thrust

bearing (See Figure 132). The clearance should

be:

0.032 mm - 0.144 mm or

0.001 in. - 0.006 in.

25. Using a feeler gauge, check the clearance between

the 4th drive gear and the 3/4 drive gear thrust

bearing (See Figure 133). The clearance should be:

0.057 mm - 0.219 mm or

0.002 in. - 0.009 in.

IMPORTANT: There are no selective washers to

adjust end play. If clearance is not within

specifications, there is either a misassembly

problem or worn parts.

26. Remove the first clutch drum assembly and case

bearing and set aside for later transaxle

reassembly.

Figure 130

Figure 131

Figure 132

Figure 133

63

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information