Saturn Transmission. Manual - part 14

CLUTCH DRUM AIR TEST AND CLEARANCE CHECK

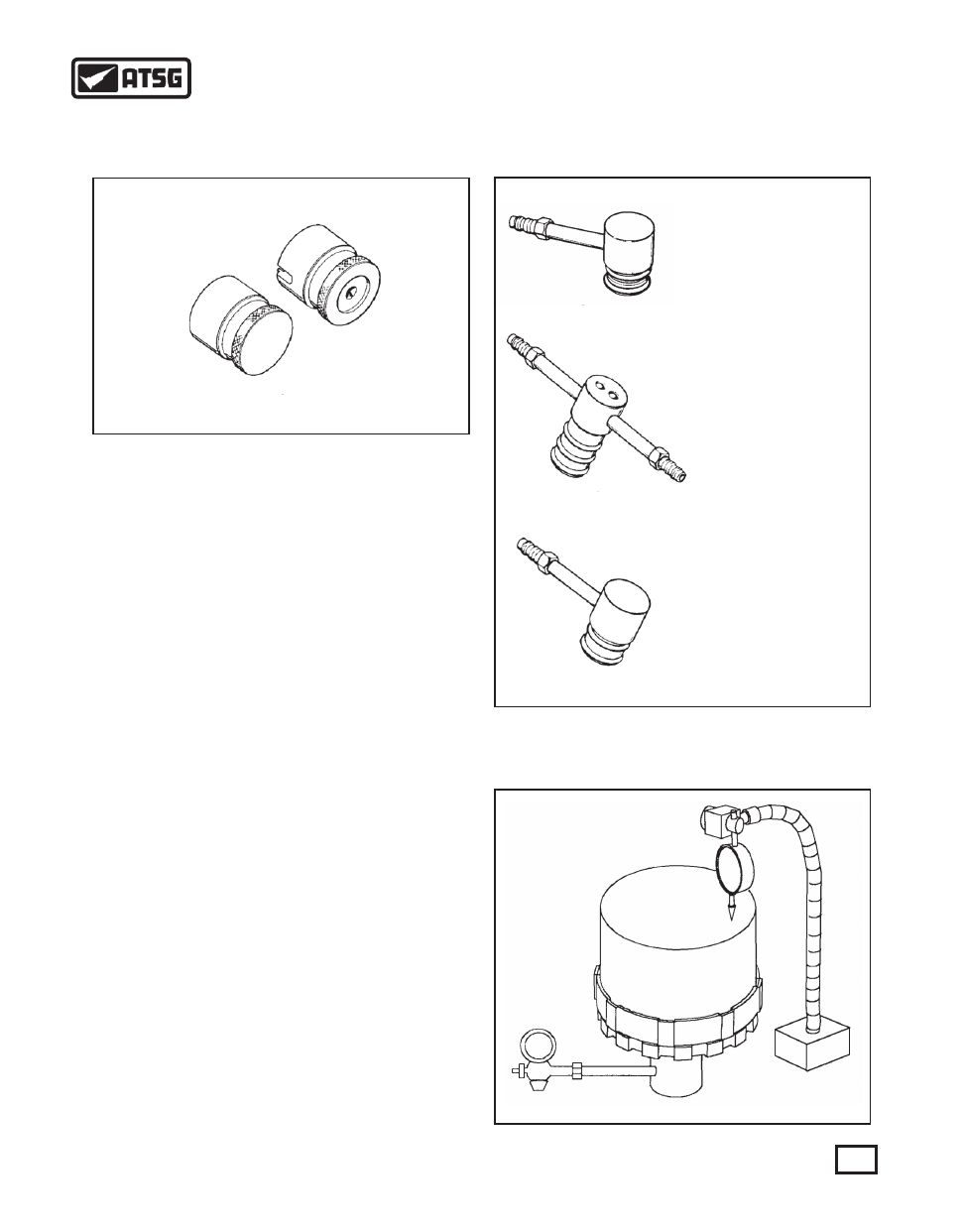

Figure 119

SA91111T-1 TOP WEIGHT

SA91111T-2 BOTTOM WEIGHT

SA9147T 1ST GEAR

AIR CHECK TOOL

SA9109T 2ND & 3RD

AIR CHECK TOOL

SA9110T 4TH

AIR CHECK TOOL

Figure 120

Figure 121

AIR AND CLUTCH CLEARANCE TEST

1. To perform this test, Saturn's tools are required.

2. Place both weights (See Figure 119) onto the clutch

backing plate as shown in Figure 121. Both

weights must be used in order to achieve an

accurate reading.

3. Install the appropriate air check fixture tool to the

clutch housing (See Figure 120).

A) 1st clutch drum.........................SA9147T

B) 2nd & 3rd clutch drum.............SA9109T

C) 4th clutch drum........................SA9110T

4. Position a dial indicator with the tip resting on the

top of the weight (See Figure 121).

5. Apply regulated air pressure to the clutch piston

through the air check tool.

A) 1st clutch piston.........................415 kPa (60 psi)

B) 2nd, 3rd and 4th clutch pistons..550 kPa (80 psi)

6. Zero dial indicator. Apply the regulated air pressure

and measure the piston travel. If end play is not

within factory specifications, release the pressure

and change the selective backing plate retaining

snap ring (See Figure 118 on page 58).

CLUTCH PACK END PLAY

1st 0.960 - 1.410 mm (.038" - .055")

2nd 1.520 - 2.190 mm (.060" - .086")

3rd 1.170 - 1.560 mm (.046" - .061")

4th 0.910 - 1.180 mm (.036" - .046")

59

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information