Porshe 911 (997). Manual - part 393

resistance spot-welding are not permitted since the thermal effect would destroy the bonded joint over a

wide area. → 5000IN IN - Processing structural body adhesives - section on "Welding in body

components"

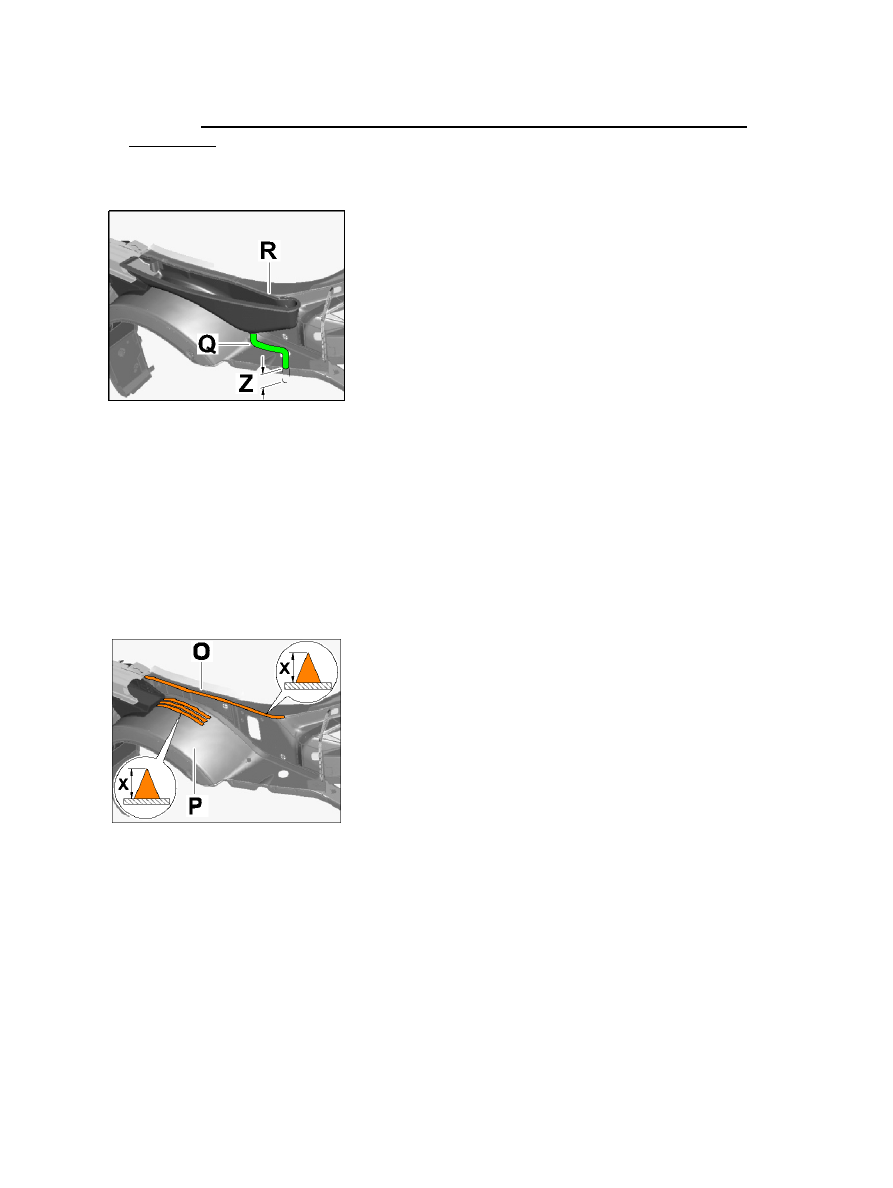

Fitting water drain hose

1. Fitting in water drain hose

Press water drain hose Q through the water drip pan R; observe specified marking. The groove of the

water drain hose must fit all the way around the hole in the water drip pan. Route water drain hose through

the grommet to the wheel housing and cut the hose so that approx. dimension Z = 35 mm projects

outwards.

2. Installing water drip pan

2.1. Apply a triangular bead of body sealant - dimension "X" = approx. 12 mm high - to the inside of

the side section O.

Applying body sealant

Apply a triangular bead of body sealant - dimension "X" = approx. 12 mm high - to the wheel

housing in area P.

Diagnostic system: reading out fault memory and activating systems

Installing side section

1729