Porshe 911 (997). Manual - part 367

Preparing connection areas of body for installing centre side

member

Safety instructions for flying sparks during grinding and welding work

ATTENTION

Danger of explosion and fire from flying sparks during grinding and welding work!

Danger of injury and danger of damage to vehicle parts and other vehicles due to flying sparks

•

→ Cover vehicle parts such as battery, fuel system, paintwork, glass and passenger compartment parts with

fire-proof covers and, if necessary, remove batteries and fuel-carrying components.

→ No other vehicles may be left unprotected in areas used for body repair!

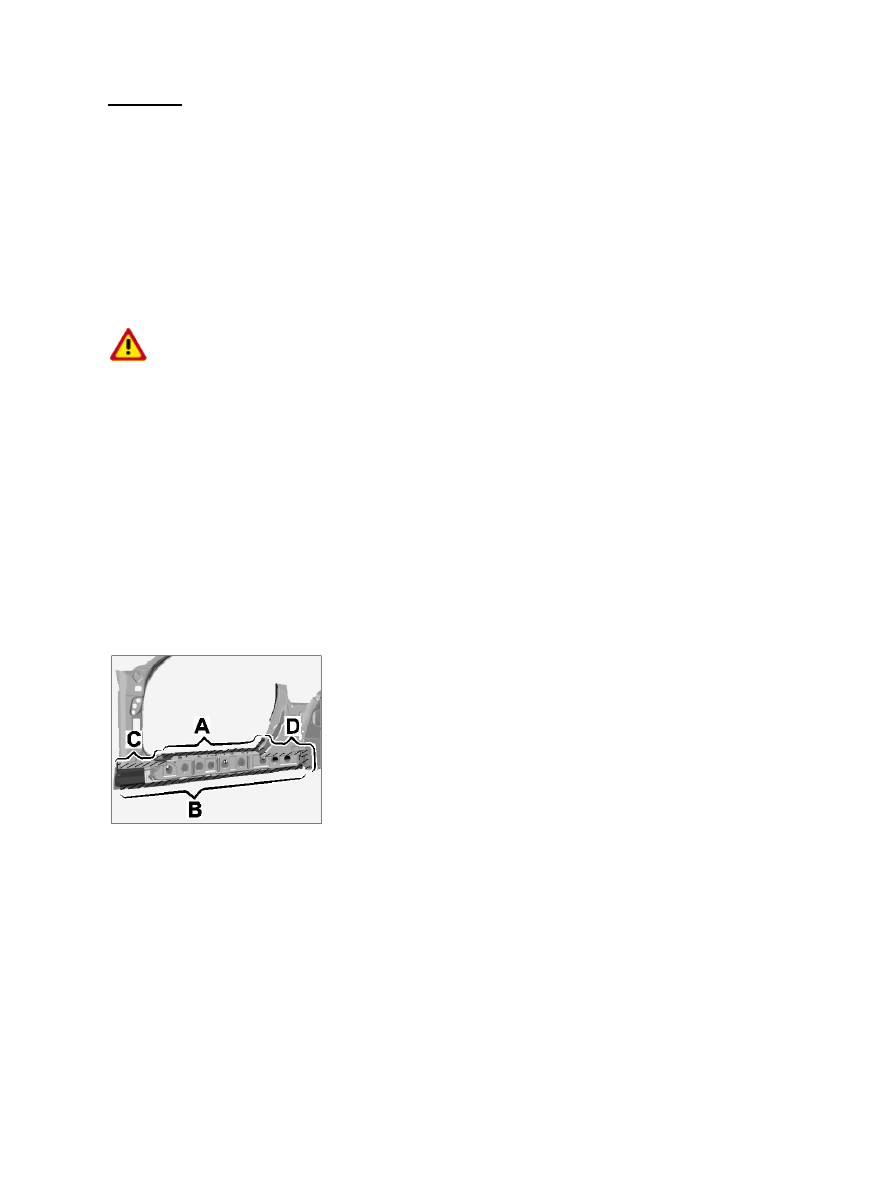

Preparing connection areas of body for installing centre side member

Preparing connection areas of body for installing centre side member

1. Clean undersealing, adhesive residue and paint off body connecting flanges in the marked areas A,

B, C, D

using a hot-air gun or rotary brush. Grind the connecting flanges until bare.

Diagnostic system: reading out fault memory and activating systems

Preparing connection areas of body for installing centre side member

1625