Porshe 911 (997). Manual - part 354

Preparing connection areas of body for installing the rear cross member

1. Clean undersealing, adhesive residue and paint off the body connecting flanges in the marked area

using a hot-air gun or rotary brush. Grind the connecting flanges until bare.

Preparing connection areas of body for installing the rear cross member

2. Clean undersealing, adhesive residue and paint off the body connecting flanges in the marked area

using a hot-air gun or rotary brush. Grind the connecting flanges until bare.

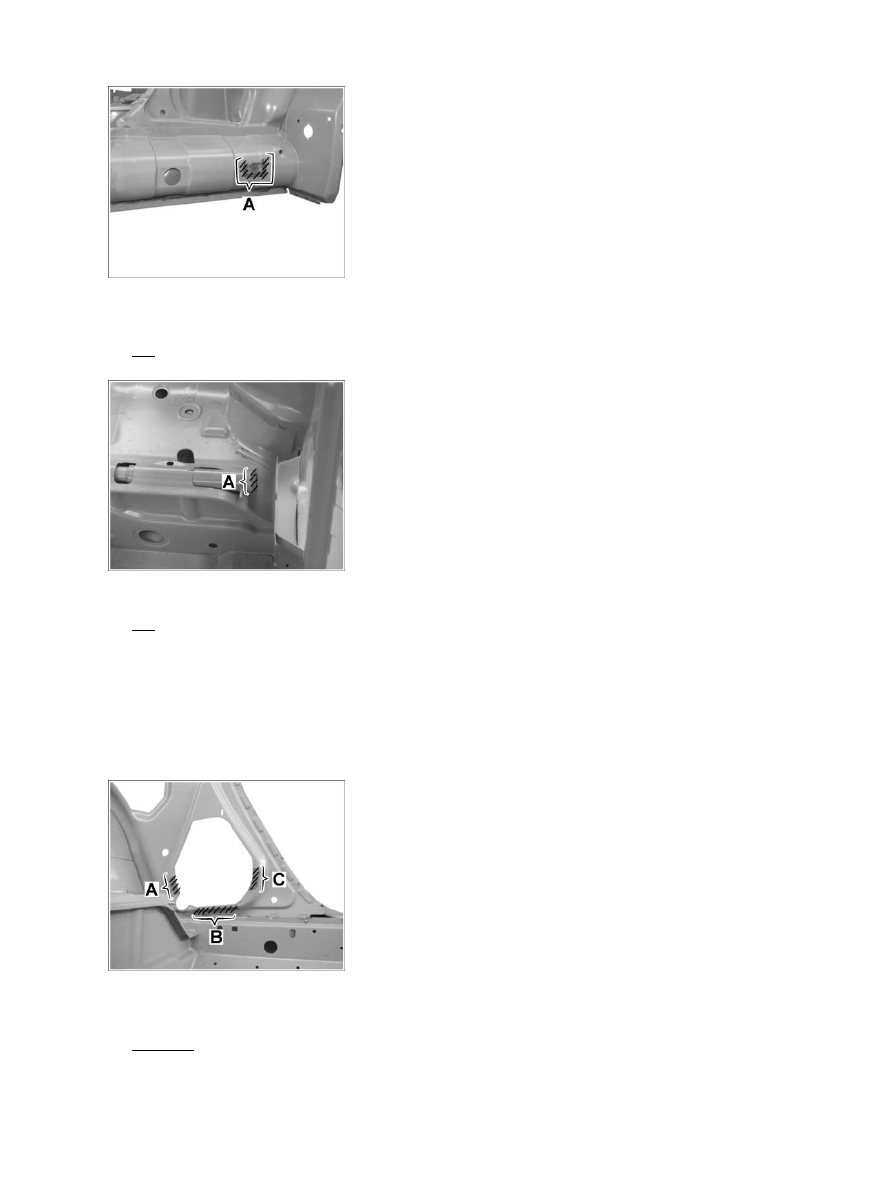

Preparing connection areas of body for installing reinforcement plate for rear

cross member

Preparing connection areas of body for installing reinforcement plate for rear cross member

1. Clean undersealing, adhesive residue and paint off the body connecting flanges in the marked areas

using a hot-air gun or rotary brush. Grind the connecting flanges until bare.

2. Coating spot-weld flange areas with zinc powder paint

Diagnostic system: reading out fault memory and activating systems

Preparing connection areas of body for installing the rear cross member

1573