Porshe 911 (997). Manual - part 351

Safety instructions for sharp-edged body and unit parts

ATTENTION

Danger of injury! Sharp-edge burrs on body and unit parts!

Injuries from sharp edges on body and unit parts.

•

→ Wear protective gloves when working in the area of sharp-edged body and unit parts!

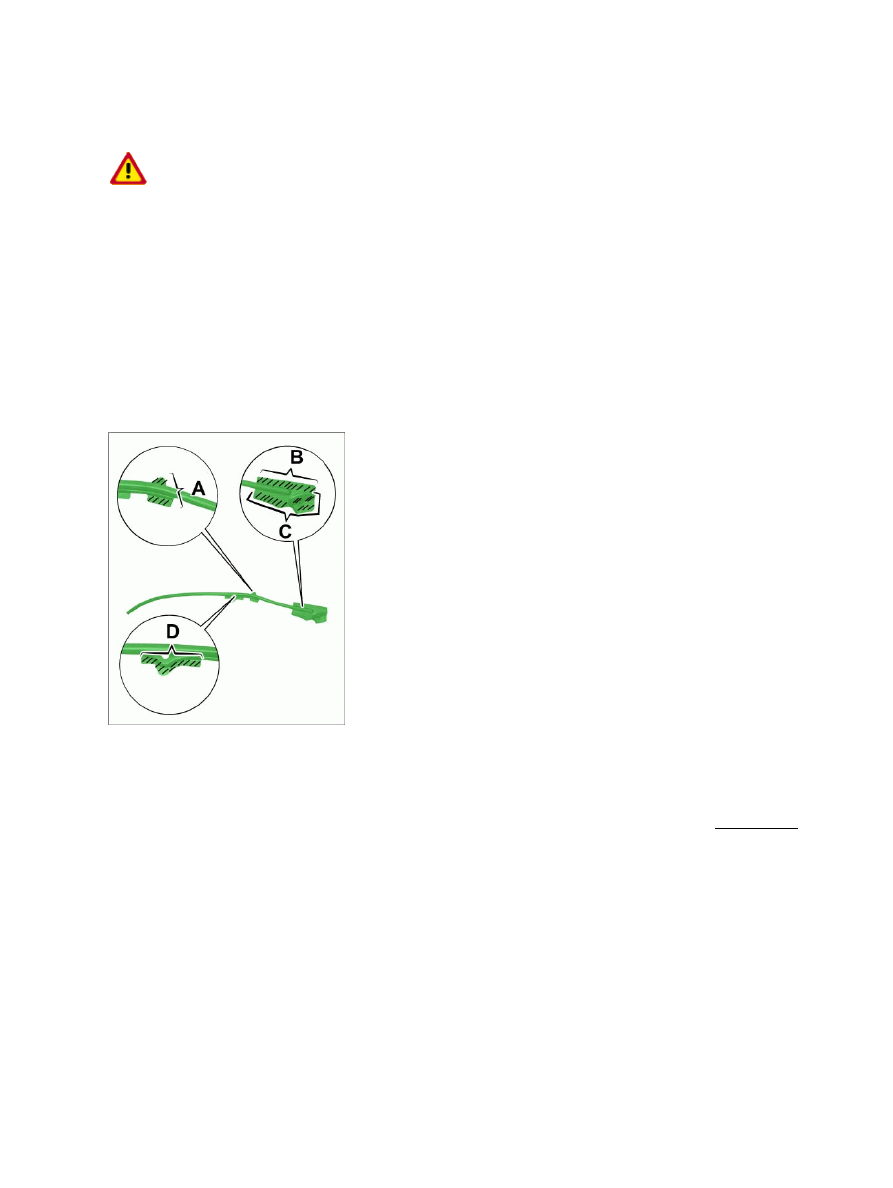

Fitting roof pillar (pipe) and preparing for installation

Cleaning the welding areas

1. Cleaning the welding

areas

bare using a rotary brush.

2. Coat spot-weld flange areas with zinc powder paint.

2.1. Coat all spot-weld flange areas with zinc powder

paint.

Fitting roof frame reinforcement and preparing for installation

Diagnostic system: reading out fault memory and activating systems

Safety instructions for sharp-edged body and unit parts

1561