Porshe 911 (997). Manual - part 293

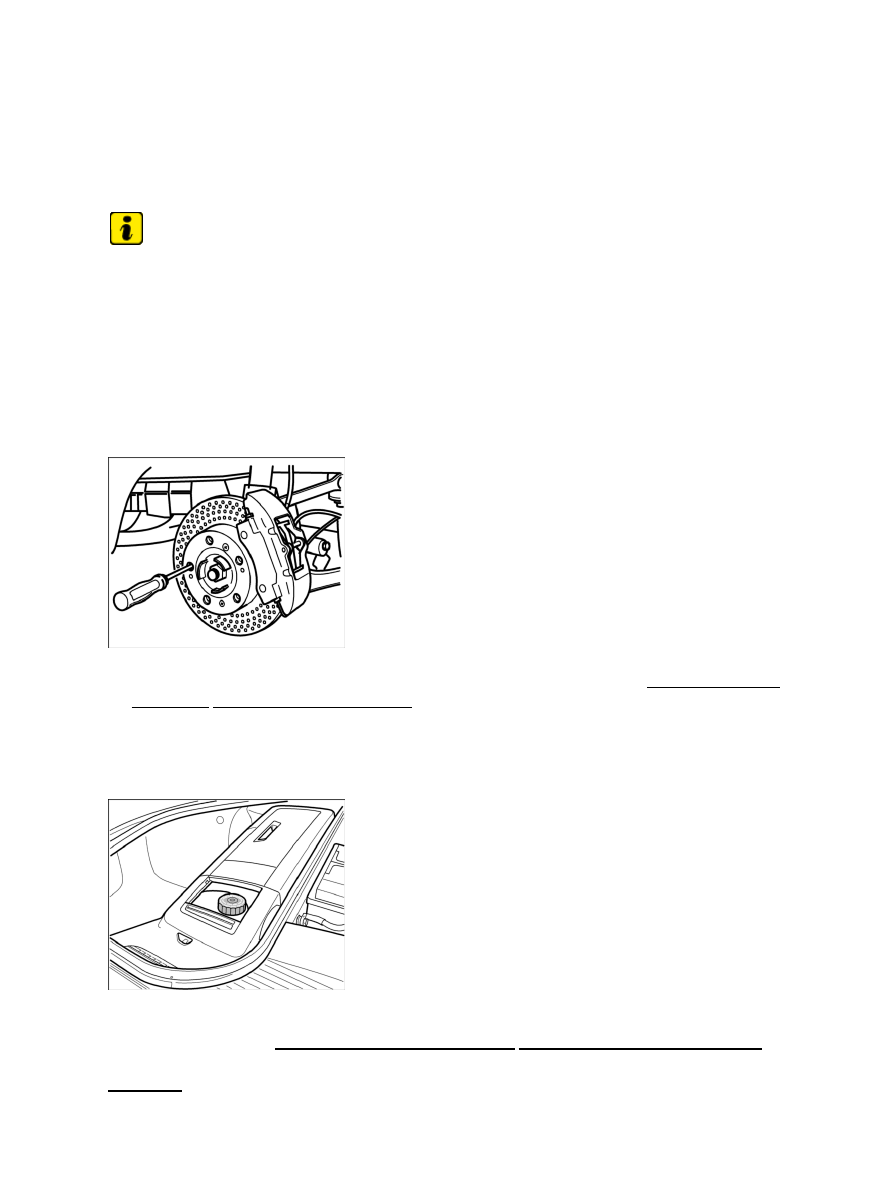

→ Use assembly aid (assembly pins) in order to exclude any possibility of heavy contact of the wheel

with the brake disc.

Do not confuse right and left brake discs during assembly!

Distinguishing characteristic: Part No.! The flat surface of the brake discs is marked with R = right or L = left.

Note

When replacing the brake discs due to wear, the brake discs on one axle must always be replaced.

Irrespective of wear, a brake disc change can be necessary on the brake disc friction surfaces due to edge

damage. In this case, only one brake disc can be replaced if the friction area surface of the other brake disc is

OK.

1. Check that all parts are in perfect condition and replace them if necessary.

2. Clean the levelling and centring surfaces on the brake disc and wheel hub. Then apply a very thin

coat of Optimoly TA to the centring surface on the wheel hub.

3. Fit the brake disc. Observe specified tightening torque. → 421000 Tightening torques for rear axle

Adjusting the parking brake

4. Adjust the brake shoes of the foot-operated parking brake with a screwdriver. → 468316 Adjusting

brake shoes → Adjusting the parking brake

5. Fit the brake calliper. Replace the brake calliper fastening screws each time they are removed.

Observe specified tightening torque. → 421000 Tightening torques for rear axle

6. Position disc brake pads by operating the brake several times.

Brake system: checking fluid level

7. Check the brake fluid level and correct if necessary. The brake fluid level must be between the

MAX-MIN marking. → Brake system: checking fluid level → 470801 Checking brake fluid level

Diagnostic system: reading out fault memory and activating systems

Installing rear brake disc

1329