Porshe 911 (997). Manual - part 191

Connecting screws

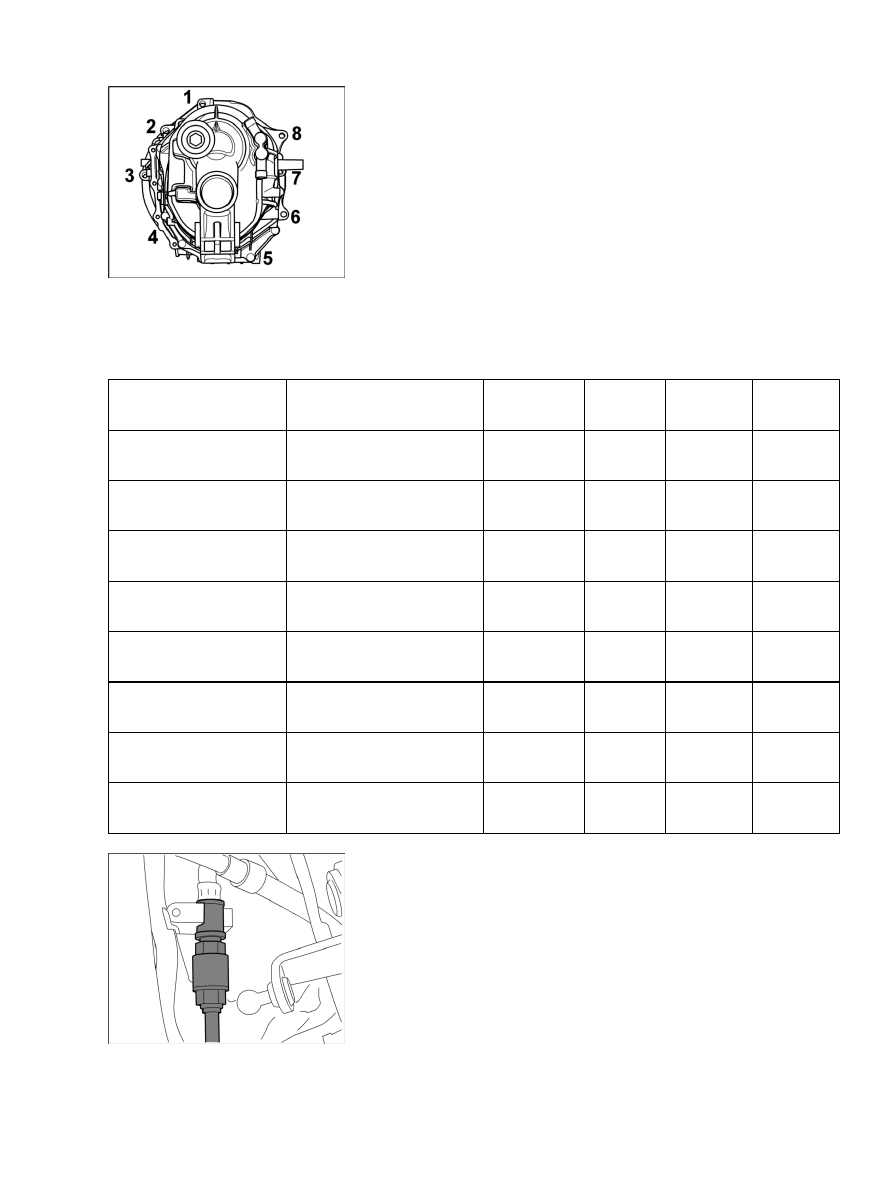

1. Guide in the transmission, and screw in and tighten the fastening

screws.

Location

Explanation

Type

Basic

value

Tolerance

1

Tolerance

2

Transmission/engine

connection

Hexagon-head bolt no. 1 in

figure, M12 x 70

Tightening

torque

85 (63

ftlb.) Nm

Transmission/engine

connection

Hexagon-head bolt no. 2 in

figure, M12 x 100

Tightening

torque

85 (63

ftlb.) Nm

Transmission/engine

connection

Hexagon-head bolt no. 3 in

figure, M12 x 100

Tightening

torque

85 (63

ftlb.) Nm

Transmission/engine

connection

Internal serration screw no.

4 in figure, M10 x 50

Tightening

torque

46 (34

ftlb.) Nm

Transmission/engine

connection

Hexagon-head bolt no. 5 in

figure, M10 x 50

Tightening

torque

46 (34

ftlb.) Nm

Transmission/engine

connection

Hexagon-head bolt no. 6 in

figure, M12 x 50

Tightening

torque

85 (63

ftlb.) Nm

Transmission/engine

connection

Hexagon-head bolt no. 7 in

figure, M12 x 70

Tightening

torque

85 (63

ftlb.) Nm

Transmission/engine

connection

Hexagon-head bolt no. 8 in

figure, M12 x 70

Tightening

torque

85 (63

ftlb.) Nm

Clutch line

2. Remove plug from hydraulic line of clutch control and fit the line.

Diagnostic system: reading out fault memory and activating systems

Installing transmission

921