Porshe 911 (997). Manual - part 131

Plastic lines

4. For better access, secure the lines and hoses to one side with a tie-wrap → Plastic lines .

ATTENTION

Material damage through lowering engine

Cables and coolant hoses can be stretched and torn

•

→ Lower the engine with a jack no more than 40 mm maximum

5. Support the engine with a jack. Unscrew the two collar nuts of the rear engine mounts. Lower the

engine by 30 - 40 mm . Should the period between removal and installation be extended, the engine

must be lifted back into position and temporarily secured with the collar nuts. Attach an appropriate

warning notice.

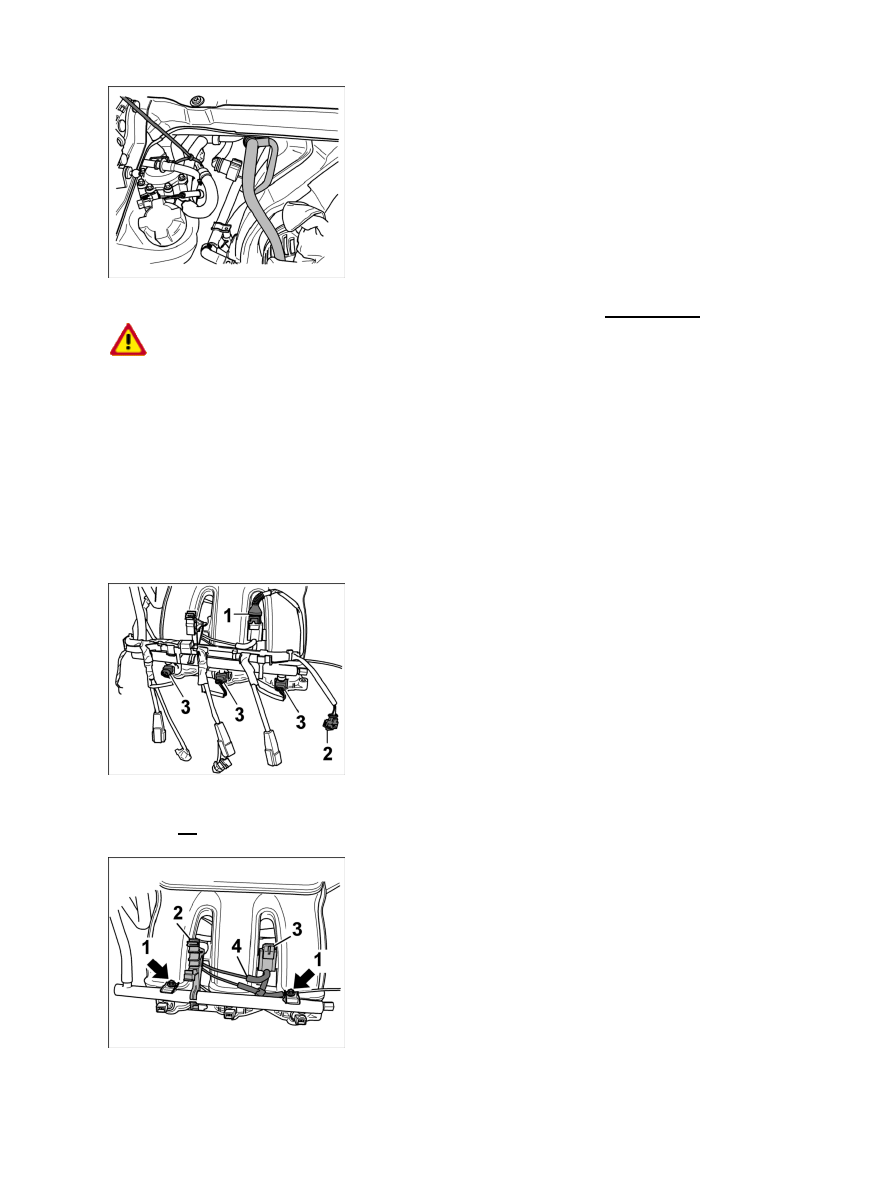

Cable plug for injection valves

6. Remove cable duct on the fuel distributor pipe. To do this, pull cable plug from camshaft position

sensor -2- and lift up cable duct.

Fuel distributor pipe

7.

Diagnostic system: reading out fault memory and activating systems

Removing injection valves of cylinder bank 1-3

681