Porshe 911 (997). Manual - part 69

Note

Always observe specified engine number range.

2. Grease fitted bore in crankcase and new bearing cover (with new sealing ring) with special grease

Optimoly MP3 (available from Porsche Parts Service) and place bearing cover in position.

Note

Replace collar nut M8 x 1 and coated M6 screws for bearing cover.

•

3. Position three new, coated M6 x 20 screws on the crankcase and pull in the bearing cover by

screwing in the screws uniformly. Tighten the screws. → Tightening torque: 10 (7.5 ftlb.) Nm

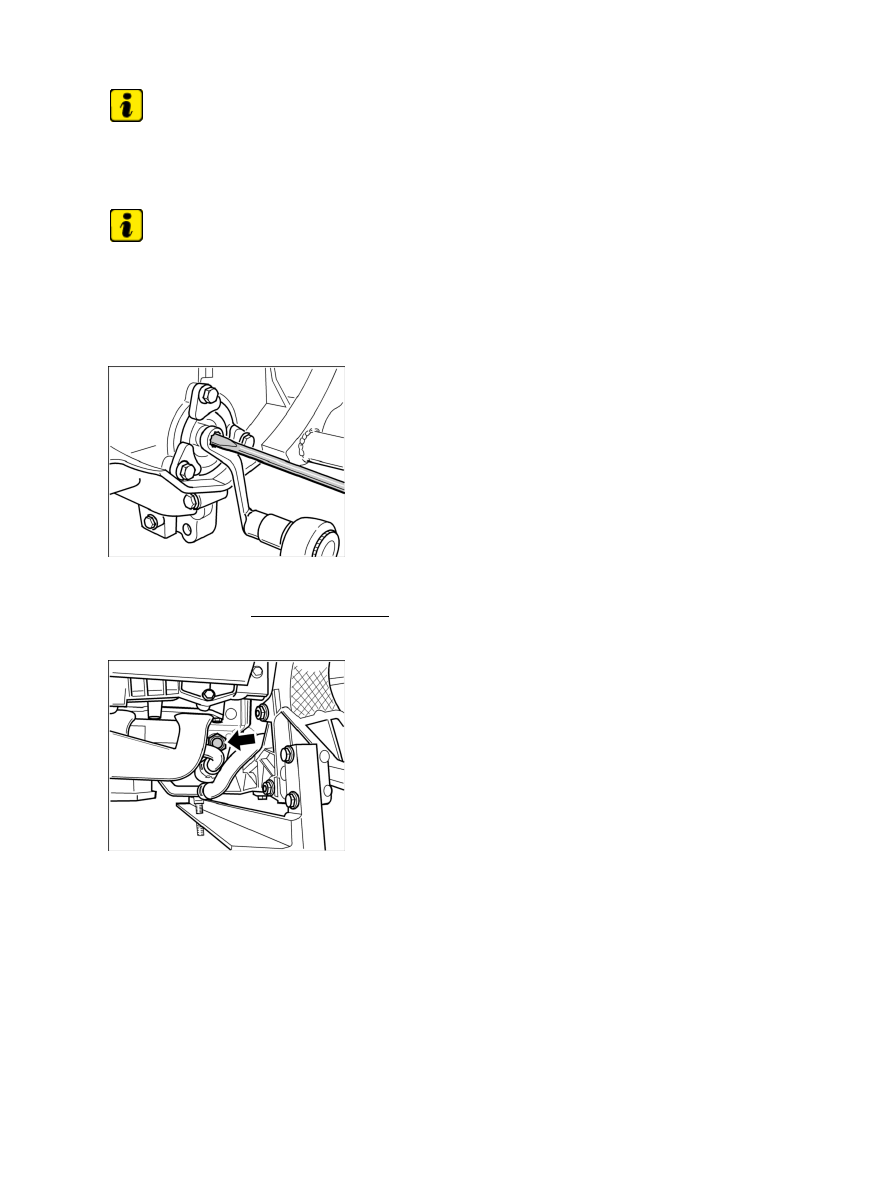

Collar nut for bearing cover

4. Position new M8 x 1 collar nut on the threaded pin of the intermediate shaft. Then tighten the nut

using special tool socket wrench 9110. At the same time, counter with a screwdriver in the slotted

threaded pin of the intermediate shaft. → Tightening torque: 12 (9 ftlb.) Nm +1 (0.5 ftlb.) Nm

Primary chain tensioner

5. Insert primary chain tensioner with new sealing ring (hexagon a/f 32) and tighten to the specified torque.

→ Tightening torque: 80 (59 ftlb.) Nm

Diagnostic system: reading out fault memory and activating systems

Installing bearing cover for intermediate shaft - up to engine number 685 09 790

433