Porshe 911 (997). Manual - part 62

Installation position of housing

Note

Do not interchange the thrust bearings of the inlet and exhaust camshafts during assembly; observe

identification markings.

•

with the guide rail for the timing chain.

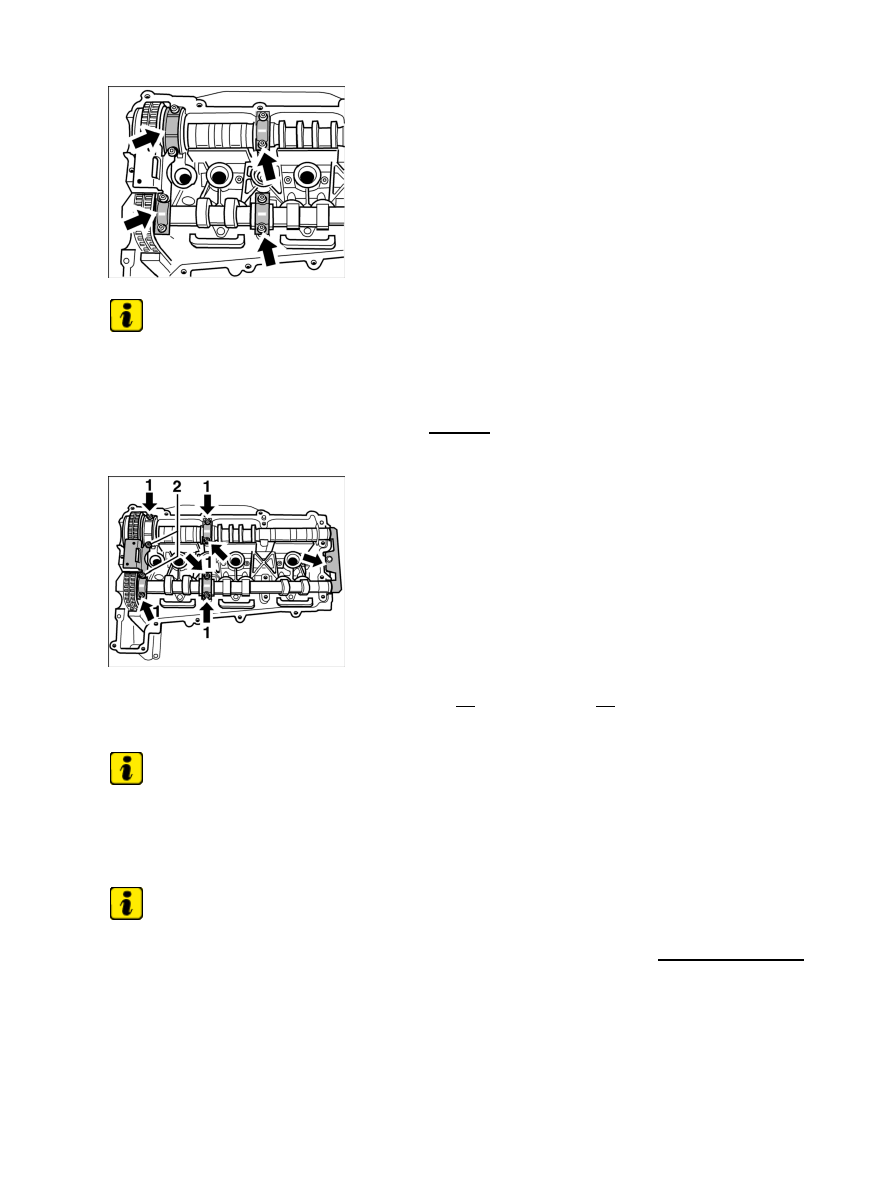

Position of housing screws

30. Insert eight housing screws (Torx): six M6 x 35 -1- and two M6 x 40 -2- for camshaft bearing and guide

rail. Tighten screws evenly and just finger-tight.

Timing for side 1 - 3

Note

Position crankshaft above the pulley or vibration balancer before final adjustment of the timing to the

TDC marking.

•

Note

Before final tightening (torque angle) of the central screw, the special tool adjusting gauge 9686

must be removed.

•

31. Final timing adjustment for cylinder bank 1 - 3 is analogous to that for cylinder bank 4 - 6. ;

Diagnostic system: reading out fault memory and activating systems

Installing camshafts, adjusting timing - engine removed

405