Porshe 911 (997). Manual - part 26

Removing piston pins

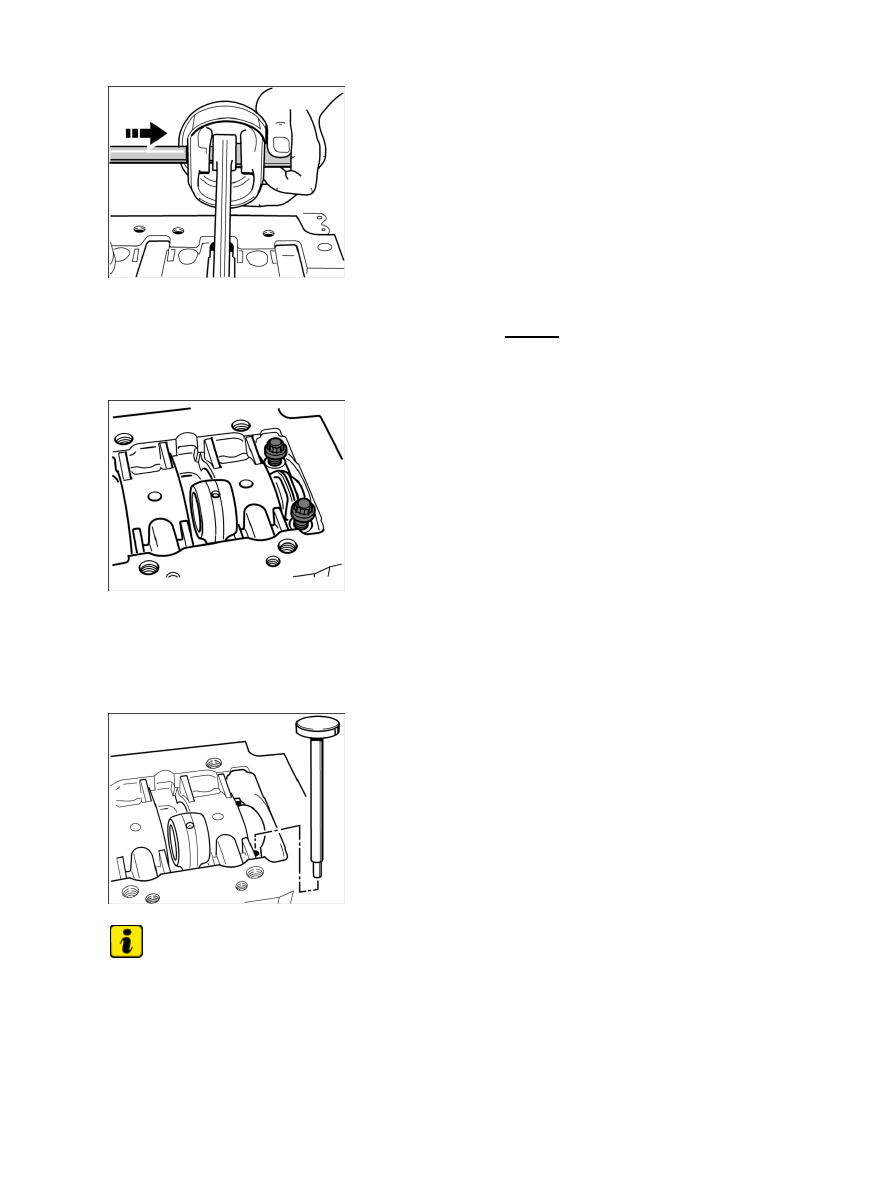

10. Lever off the front piston-pin circlips of marked pistons 4-6 (from the viewpoint of the drive belt

side) using a small screwdriver, push out the piston pin -arrow- and remove the pistons one by

one. Assign the piston pins again to the appropriate pistons.

Removing pistons and connecting rods, side 1-3

Connecting rod bolts

11. Remove marked pistons 1-3, including connecting rods. To do this, turn the crankshaft on the

belt pulley/vibration balancer until the respective connecting rod bearing cap stands upwards.

Undo and remove the connecting rod bolts (twelve-edged socket wrench insert a/f 14), remove

connecting rod bearing cap.

Removing connecting rod using plastic mandrel (shop-made)

Note

Join connecting rod and connecting rod bearing cap together again immediately after removal.

•

Connecting rod bolts must be replaced.

•

12. Carefully press connecting rod and pistons downwards out of crankcase half 1-3 using a

Diagnostic system: reading out fault memory and activating systems

Removing pistons

261