Porshe 911 (997). Manual - part 25

cover for dust protection

when fitting the engine

commercially

available tool

NR.165

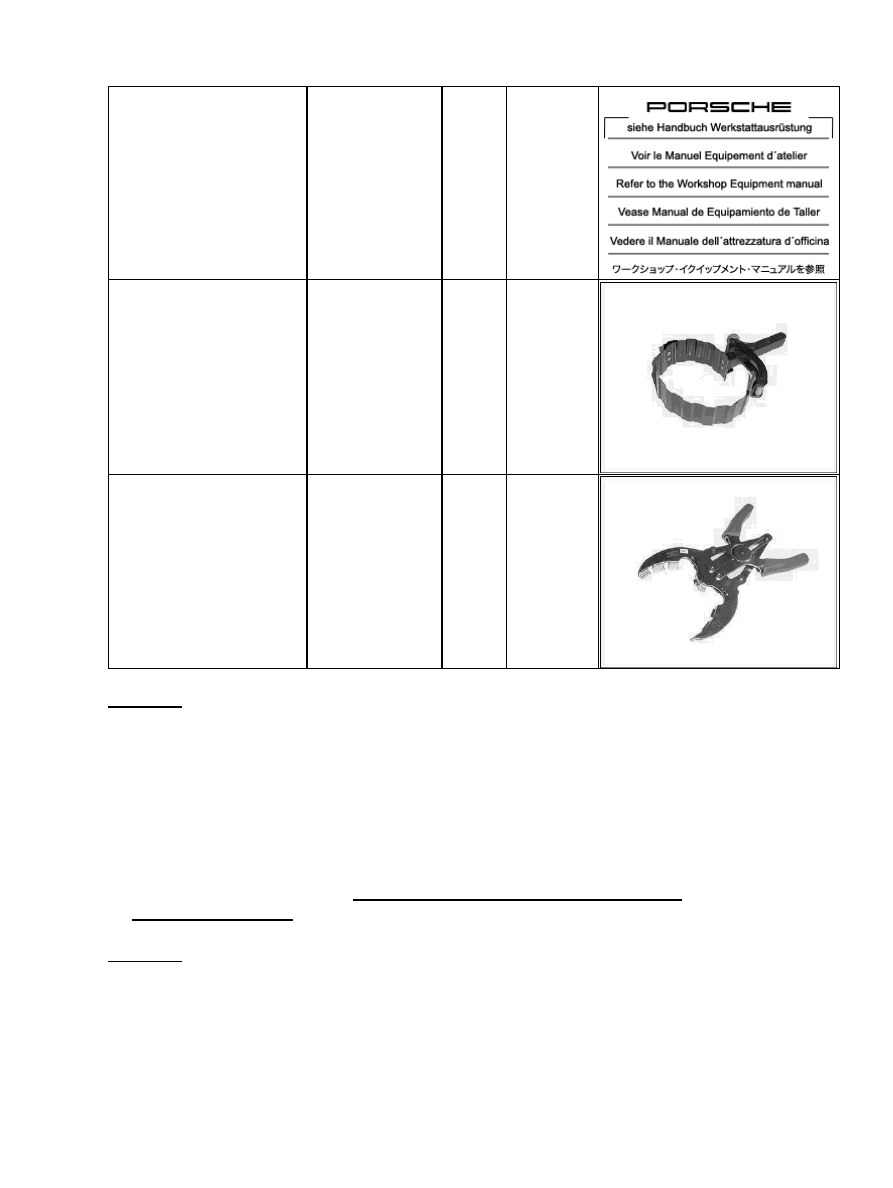

universal piston ring

restraining strap, 75 - 125

mm

commercially

available tool

NR.55

piston ring pliers Gr. 1

commercially

available tool

NR.58

Removing pistons, preliminary work

Removing pistons, preliminary work

1. Disassemble engine to crankcase → 100137 Disassembling and assembling engine -

Removing pistons

Diagnostic system: reading out fault memory and activating systems

Removing pistons, preliminary work

257