Porshe 911 (997). Manual - part 12

Cross member with accessories

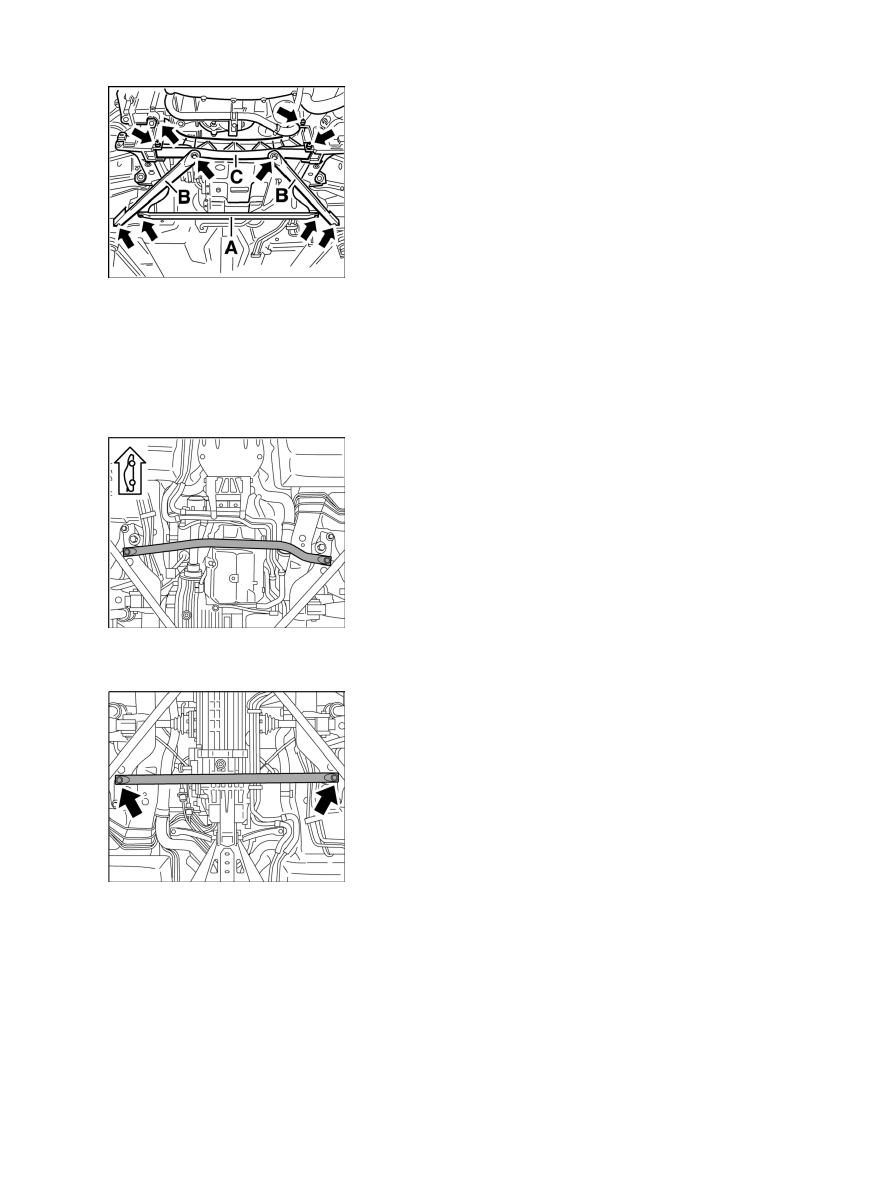

14. Install chassis components:

14.1. Rear cross member: M12 hexagon-collar nuts → Tightening torque: 74 ftlb.

14.2. Diagonal braces on rear cross member: hexagon-head bolt → Tightening torque: 74 ftlb.

14.3. Diagonal brace on rear-axle support: collar nut → Tightening torque: 48 ftlb.

14.4. Diagonal brace to body: hexagon-head bolt → Tightening torque: 48 ftlb.

Transverse strut, Tiptronic

15. Front transverse strut, Tiptronic transmission: hexagon-head bolt → Tightening torque: 48 ftlb.

Transverse strut, manual transmission

16. Transverse strut, manual transmission: hexagon-head bolt → Tightening torque: 48 ftlb.

Diagnostic system: reading out fault memory and activating systems

Installing engine

205