Engine International HS 2.8L. Manual - part 16

International HS 2.8L

Pistons and Connecting Rods

7 3

8120081 - 05/02 - Service Manual

INTERNATIONAL ENGINES

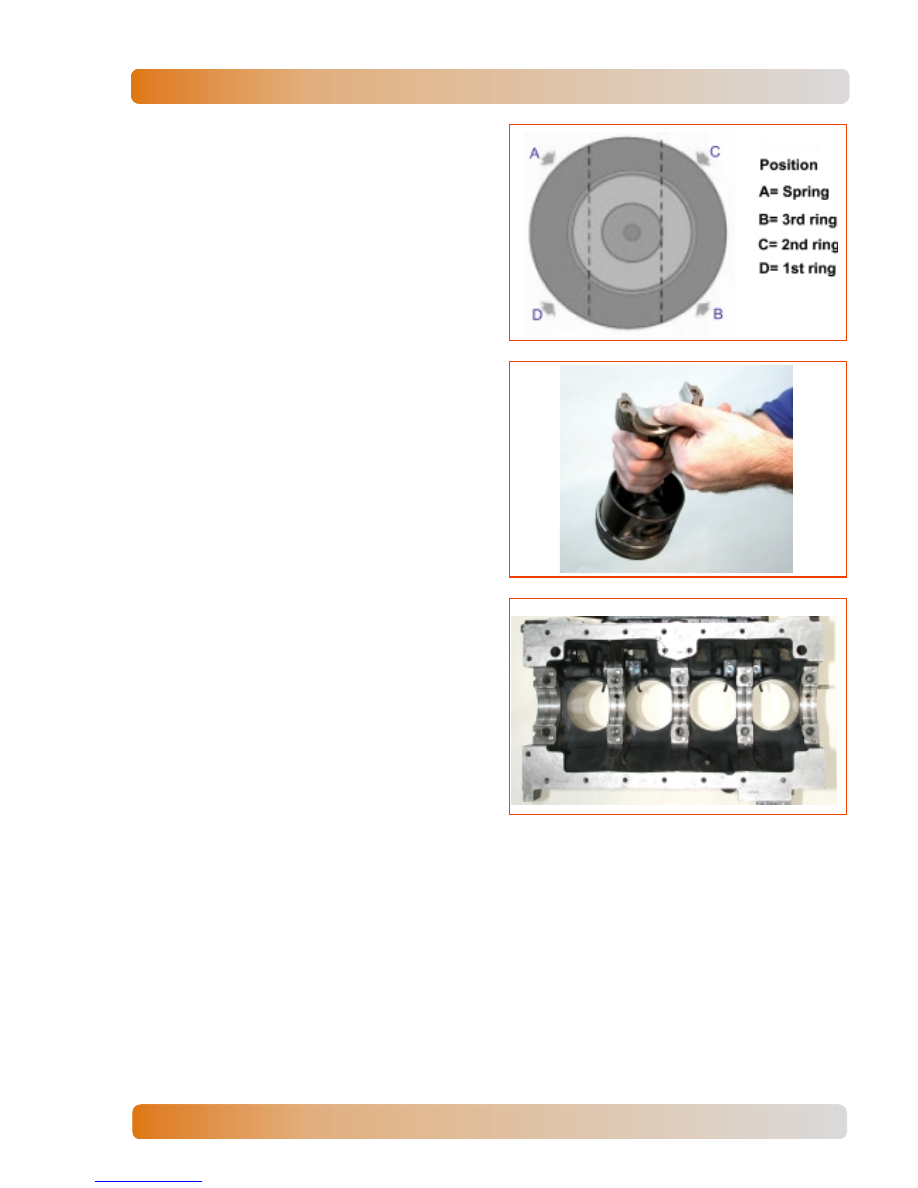

3.

Assembly ring spring in piston 3rd groove

and next ring, with ends in opposite position

from spring ends. Install 2nd and 1st rings

with TOP mark or inner chamfer upwards.

Note that 2nd and 1st grooves rings have

different thickness.

4.

Clearances between rings ends must not be

aligned in the same direction of piston pin or

skirt. Position rings according the illustration.

5.

Assembly new shells on connecting rod

body, correctly positioning locks.

Installation

1.

Set engine block in horizontal position.

Lubricate grooves, inside liners, connecting

rod shells and crankshaft crankpin.

2.

When assembling piston, make sure that the

arrow is aiming the engine front side. Install

connecting rod with the tool nr. 8130646,

avoiding scratching the liner.

3.

Assembly piston in cylinder, using tool nr.

8130647 and a rod of wood to push the

piston.

4.

In turbocharged engines, there is one injector

of lubricant oil for each engine cylinder.

During piston assembly in the cylinder, check

the position of the connecting rod in relation

to the injector, avoiding breaking its injection

pipe.

5.

The positioning of the oil injector inside the

engine block is checked with the engine

viewed from the top, without cylinder head.