Engine International HS 2.8L. Manual - part 15

International HS 2.8L

Pistons and Connecting Rods

6 9

8120081 - 05/02 - Service Manual

INTERNATIONAL ENGINES

PISTONS AND CONNECTING

RODS

Removal

1.

Remove cylinder head.

2.

Remove oil pan, suction and lubricant oil flux

pipes.

3.

Position the block in the horizontal position.

4.

Before removing piston, remove carbon

deposits accumulated on liner top.

Horizontally position cylinders and cylinder

piston to be cleaned at BDC. Fill with a cloth

the space above of the top of the piston.

Remove carbon with a brush or sandpaper

and clean the area with a cloth.

4.

Remove pistons.

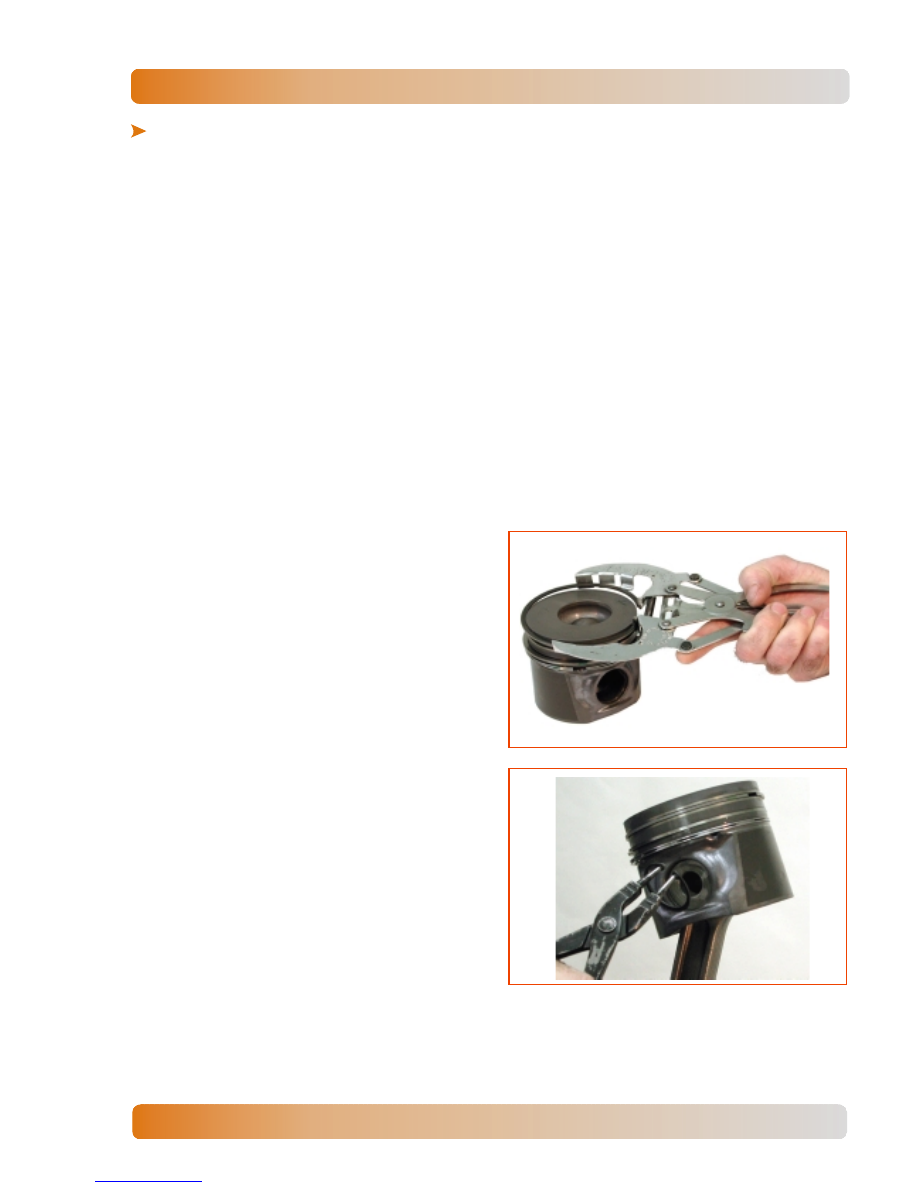

Disassembly

1.

Remove the piston rings.

2.

Remove snap rings and manually remove

piston pin. If it is difficult to remove pin, heat

the piston in water or oil up to 80 °C (176 °F).

3.

Remove connecting rod bushing.