Engine International HS 2.8L. Manual - part 9

International HS 2.8L

Lubrication System

4 2

INTERNATIONAL ENGINES

LUBRICATION SYSTEM

PREVENTIVE MAINTENANCE

The lubrication system is responsible for the

durability and internal cleaning of the engine.

Beyond of lubricating, the oil has the function of

absorbing the heat generated by the friction of the

mobile parts.

Level

Check oil level with the engine on a flat ground

and stopped.

1.

Wait from 10 to 15 minutes to allow the oil

return from the upper part of the engine.

2.

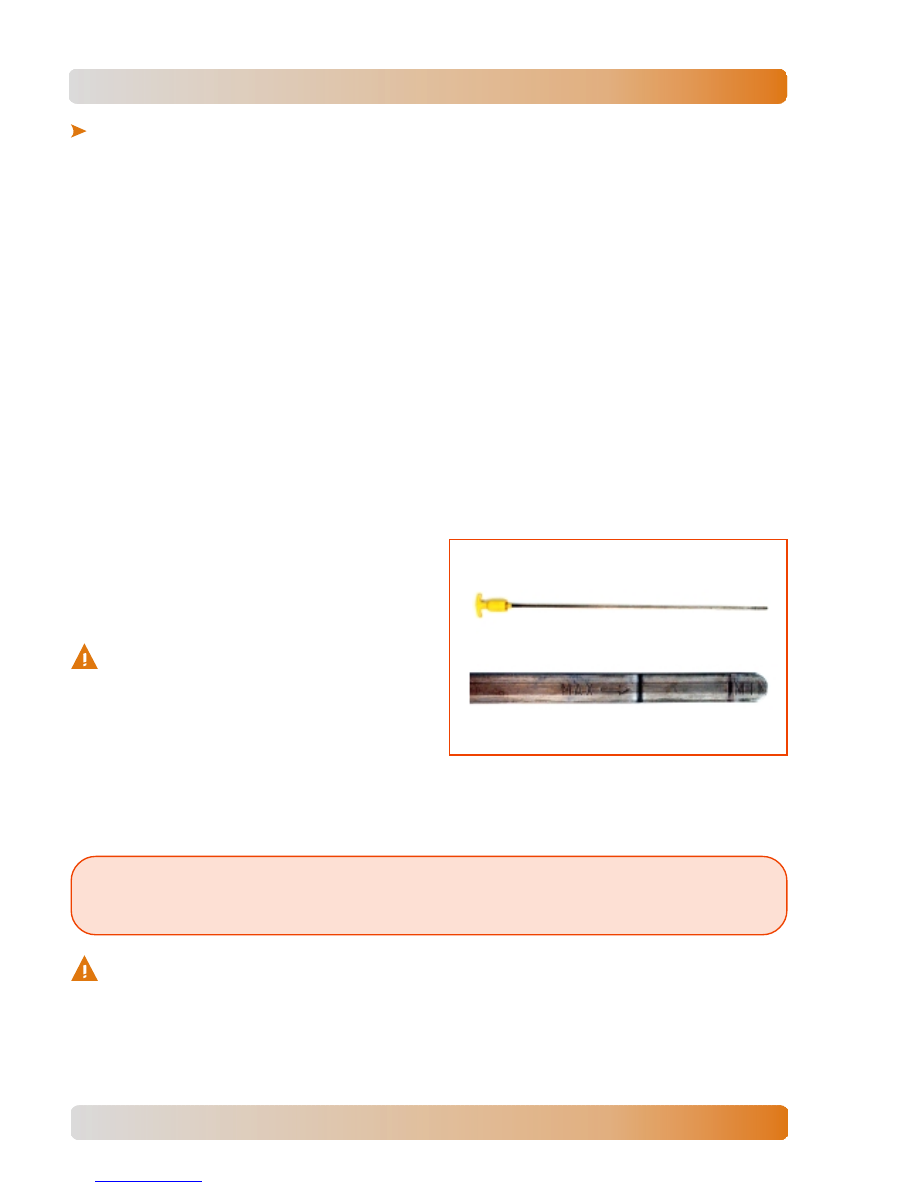

Remove oil dipstick and clean it with a clean

cloth, introduce it until the edge, remove it

again and check level, twice, to make sure of

the check.

Complete the oil level only if the oil mark is below

the dipstick lower mark, the difference between

the volume of the maximum mark and the

minimum mark is 1 liter. Always use oil of the

same specification.

Warning:

If oil level is frequently low, seek

a distributor and / or authorized

service.

Lubricant oil and filter replacement

If the engine operates in regions with high dust

concentration, or other harmful conditions to the

good operation, it will be necessary to reduce the

replacement periods, filter and lubricant oil.

Note:

After the first oil and filter change at 15,000 km (9,300 mi) or 6 months, prevailing which

one occurs first, lubricant oil must be replaced together with filter.

Warning:

During drainage, lubricant oil is

hot and may cause burnings.