Engine International HS 2.8L. Manual - part 3

1 5

International HS 2.8L

Operation and Maintenance Recommendations

8120081 - 05/02 - Service Manual

INTERNATIONAL ENGINES

INSTALLATION REVISION

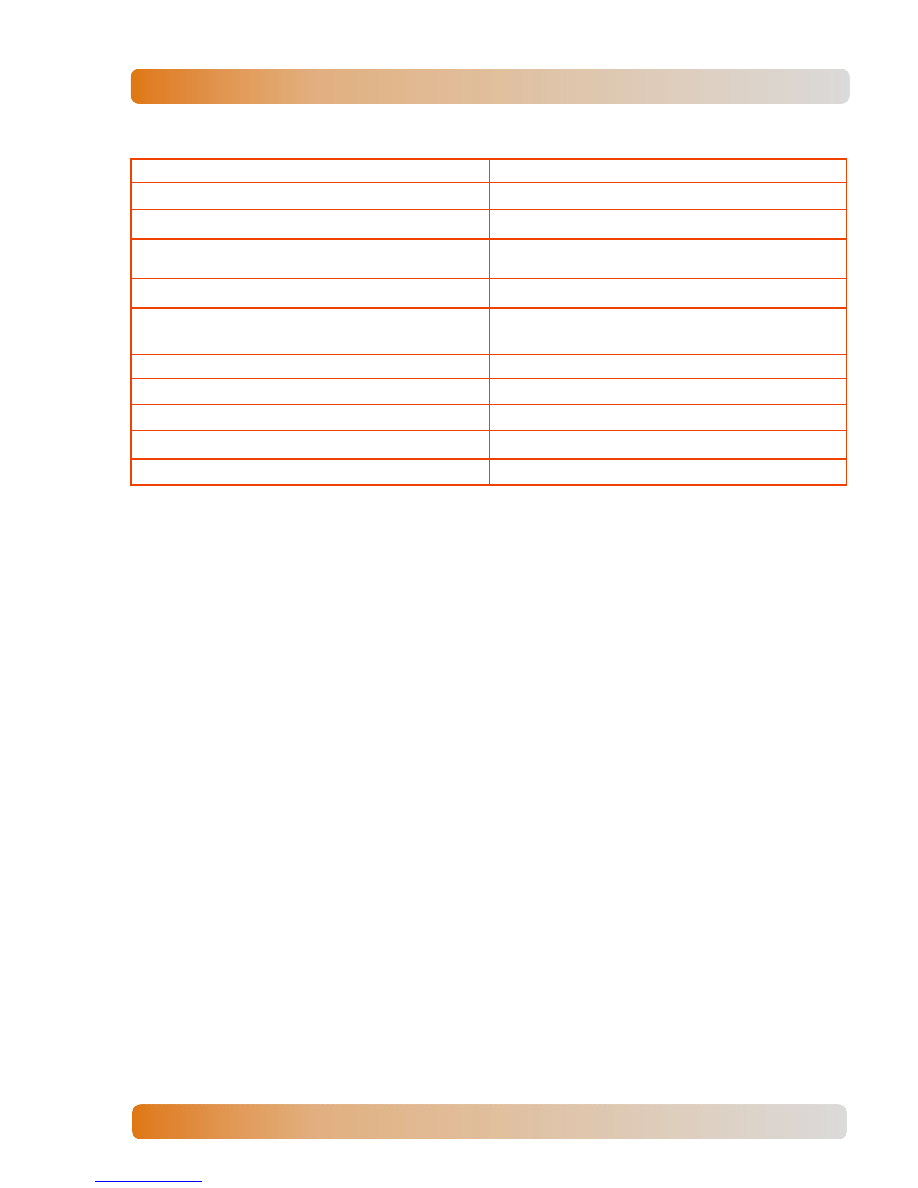

ITEM

CHECK

Alternator belt

Tension

Water and lubricant oil

Level (complete if necessary)

General performance

Operation temperature and speed at

maximum load

Intake system

Intake air temperature and restriction

Fuel system circuit

If the piping is unobstructed and free of vibrations,

extreme heat areas and leakages occurrences

Exhaust system

If there isn’t restriction to the exhaust gases

Command system

Accelerator course

Engine fixation

Alignment among engine and transmition

Instrument panel

Indicators, warning lamps and sensors functioning

Cooling system

Radiator, hoses, piping and clamp conditions